In the upcoming chapters, we’ll reveal the delicate manufacturing process behind rubber gym flooring. You’ll get an industry insider’s perspective on how each piece of quality flooring is produced so that you can be confident that rubber gym flooring will meet the demanding requirements of a fitness environment. Understanding the processes involved in creating these durable surfaces will equip you with the knowledge to assure your customers of their superior quality.

How do you select and purify raw materials?

When it comes to the manufacturing of rubber gym flooring, it starts long before rubber makes its way into gym flooring. It starts with rigorous screening and purification of the recycled rubber. As a distributor, you need to be sure that you’re providing a product that is not only durable and high-performing but also safe and clean. Here’s how manufacturers ensure this:

Selecting Reclaimed Rubber:

The process begins with a careful selection of recycled rubber materials. Manufacturers source from reputable suppliers who collect discarded rubber products, such as old tires, known for their durability and resilience. However, not all recycled rubber is created equal. Before converting it into gym flooring, it must first pass a rigorous quality assessment.

Decontamination process:

Once the rubber has been selected, the decontamination process begins. This involves crushing the rubber into granules and passing it through several cleaning stages. Advanced mechanical equipment is used to screen the material and remove metals, fibers, and other impurities that could affect the quality of the flooring.

Purification:

The granules are then further purified to remove any residual impurities. This may include washing with water and environmentally friendly detergents, as well as using a magnetic separator to extract the smallest metal fragments. The purpose of this is to ensure that the reclaimed rubber is as pure as possible before it is converted into gym flooring.

Quality Assurance:

Before moving on to the next production stage, the purified rubber undergoes quality assurance tests. These tests are designed to detect any residual contaminants and assess the physical properties of the rubber. Only batches that meet stringent purity and performance criteria are approved for the next production stage.

At the end of this meticulous process, producers are left with clean, high-quality reclaimed rubber to turn into the robust and reliable gym flooring that customers trust. This commitment to thorough material preparation sets high-quality gym flooring apart from other products, ensuring safety, performance, and longevity.

As a distributor, this detailed approach to material preparation allows you to assure your customers that the rubberized gym flooring you provide is not only durable but also made with their health and safety in mind.

Which non-toxic adhesives are used in rubberized gym flooring?

The bonding process is crucial when producing rubberized gym flooring. This is where the granulated rubber is transformed into a solid and durable surface ready for use. But what brings it all together? The answer lies in the adhesives used.

Manufacturers know the health implications of the volatile organic compounds (VOCs) in many adhesives. As a result, industry standards have shifted toward using non-toxic adhesives that do not contain harmful chemicals. These adhesives are water-based and solvent-free, ensuring that they do not impact indoor air quality or pose a health risk to those who frequent gyms.

These environmentally friendly adhesives are carefully mixed with rubber granules under precise conditions to ensure a solid and long-lasting bond. As a result, this resilient flooring solution supports heavy-duty use while maintaining a commitment to health and environmental standards.

Can the colors and textures of Rubber Gym Flooring be customized for a brand?

Absolutely! Customization is the key to creating distinctive and unique spaces, and rubber gym flooring provides ample opportunity for personalization. Manufacturers understand how important branding is to a business, so they offer a variety of colors and textures to match your company’s theme or logo.

The customization process is quite complex. During the mixing stage, colored pigments can be added to the rubber granules to provide a wide range of shades. Whether you want to animate your space with vibrant colors or create a classic look with understated tones, there are various options.

As for texture, the floor’s surface can be customized during the molding process. There are everything from smooth surfaces to textured patterns that provide extra grip and add to the aesthetics of a space. This level of customization can give a truly bespoke product that reflects the brand and ethos of the client’s business.

By offering these personalization options, you can cater to the specific needs and preferences of your clients, ensuring that their fitness space is not only functional but also reflects their brand image.

How Does the Vulcanization Process Affect the Lifespan of Gym Flooring?

Vulcanization – it’s not just a fancy word; it’s the game-changing process that significantly extends the lifespan of rubber gym flooring. This isn’t just about durability; it’s about creating a product that can stand up to the daily grind of gym life for years to come.

During vulcanization, the rubber mixture is heated under pressure with sulfur. This causes new cross-links between the rubber molecules, transforming the once soft rubber granules into a robust and elastic material. It’s like turning a handful of loose threads into a tight, interwoven fabric. The result? Flooring is resistant to abrasions, indentations, and the kind of wear and tear that comes from dropped weights and constant foot traffic.

But the benefits don’t stop at durability. Vulcanized rubber flooring maintains its shape and resilience over time, meaning it won’t just last longer; it’ll look good and perform well throughout life. This process is crucial for gym owners who want to ensure their investment remains in top condition, providing a safe and stable surface for their clientele.

Does Vulcanization Minimize the Release of Harmful Chemicals?

The health of gym-goers is paramount, and the last thing anyone wants is flooring that compromises air quality. The good news is that vulcanization helps in this regard as well. By converting the rubber into a more stable material, the potential for harmful chemical release is significantly reduced.

The vulcanization process locks in chemicals that might otherwise become airborne, minimizing the off-gassing that can occur with non-vulcanized rubber products. This means that once the flooring is installed, it’s less likely to contribute to indoor air pollution, making it a safer choice for indoor environments.

Moreover, manufacturers continually refine the vulcanization process to ensure it’s as environmentally friendly as possible. By optimizing the amount of sulfur and other chemicals used and by employing state-of-the-art technology, they’re able to produce gym flooring that meets strict safety and environmental standards.

In essence, vulcanization is a win-win: it extends the life of the gym flooring and does so in a way that keeps the air cleaner and safer for everyone. As a dealer, you can assure your clients that the floors you provide are not just built to last but also built with the well-being of their users in mind.

What thicknesses are available for rubber and interlocking gym tiles?

Regarding fitness facility finishes, one size does not fit all. That’s why rubber and interlocking fitness tiles are available in various thicknesses to suit different needs and applications. The thickness of your flooring not only plays a vital role in the look and feel of your fitness space but also impacts its functionality and comfort.

Typically, rubber gym floor tiles range in thickness from 1cm to 8cm. 1cm tiles are suitable for lighter weights and low-traffic areas, while 2.5cm to 5cm tiles are designed to withstand heavy free weights and high-impact activities. For most standard gyms, 2cm to 3cm tiles offer a good balance of durability and cost-effectiveness.

Known for their ease of installation and versatility, interlocking gym tiles offer a range of thickness options. These tiles also provide the benefit of a seamless appearance, allowing individual tiles to be replaced if necessary without having to resurface the entire floor.

By offering tiles in various thicknesses, manufacturers can ensure that the unique flooring requirements of facilities ranging from yoga studios to Olympic weight rooms are met.

Can we choose different textures during the tumbling process?

Absolutely! The rolling process not only determines the thickness of the rubber gym flooring but also creates different textures. These textures are not just for aesthetic purposes but also have a functional purpose.

Manufacturers can create smooth surfaces for easy-to-clean areas, as well as firmer textures for enhanced grip and slip resistance. There are also options for diamond-shaped patterns (popular for their greater durability and traction) or softer, more cushioned patterns for floor exercise and yoga areas.

The ability to choose from a wide range of textures means that you can provide flooring solutions tailored not only to the visual branding of the gym but also to the specific activities in each area. This customization ensures the end user enjoys a safe, comfortable, and effective workout environment.

In short, the variety of thickness and texture options allows for a high degree of customization, ensuring that every gym has a floor that is as tough as the most demanding athletes and as versatile as the variety of activities they host.

Can Rubber Roll Flooring Be Custom Cut to Client Specifications?

Customization is the name of the game in today’s market, and rubber roll flooring doesn’t fall short. Yes, it can be custom-cut to meet the specific dimensions and shapes required by your clients. This bespoke approach allows for a precise fit, no matter the layout or size of the gym space.

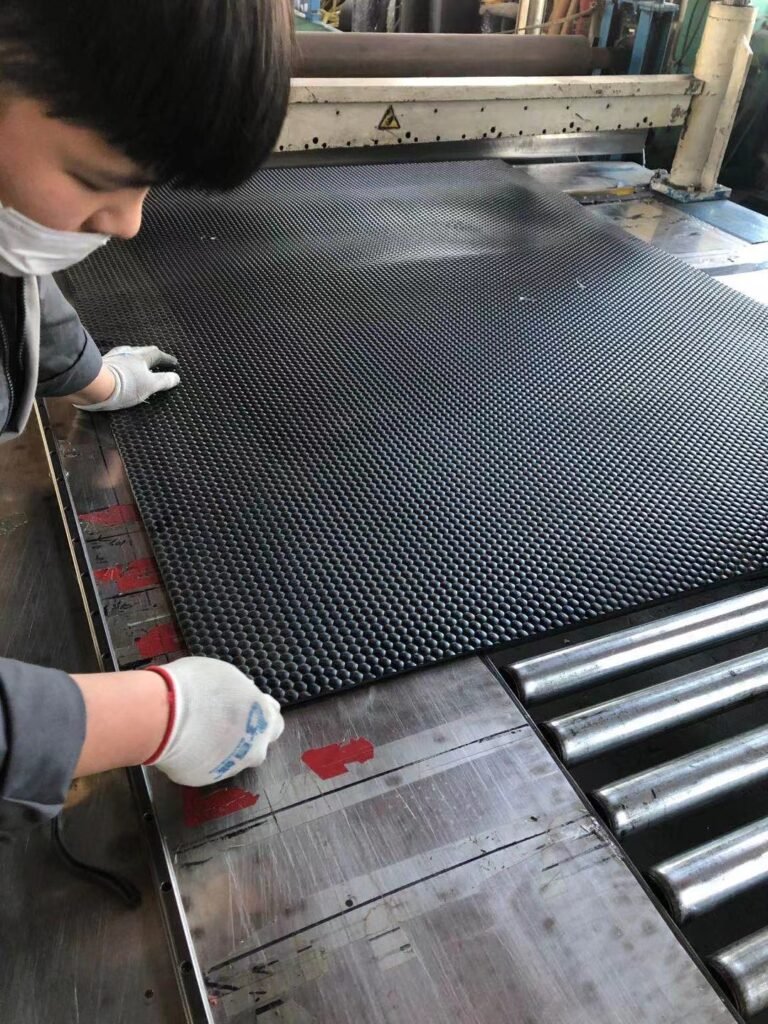

Manufacturers use advanced cutting equipment that can handle large rolls of rubber flooring with exact precision. Whether it’s for a snug corner, around tricky equipment, or expansive open areas, the cutting process is tailored to the unique blueprint of each facility. This means that dealers can offer a product that is not only functional and durable but also fits the designated area like a glove, ensuring a professional look and finish.

How is Precision Cutting Ensured for a Perfect Fit?

Precision is paramount when it comes to fitting gym flooring. To achieve this, manufacturers employ a combination of skilled technicians and state-of-the-art technology. Computer-aided design (CAD) systems are often used to map the dimensions and shapes needed. These designs are then fed into Computer Numerical Control (CNC) cutting machines, which meticulously cut the rubber flooring to the specified measurements.

Such technology ensures that every cut is sharp, clean, and consistent. It eliminates the margin for error that comes with manual cutting, ensuring that each piece of the flooring puzzle fits seamlessly together. This level of accuracy not only makes for an aesthetically pleasing finish but also eliminates tripping hazards and ensures the integrity of the flooring over time.

By guaranteeing precision cutting, manufacturers can provide you with a product that’s easy to install and meets the high standards your clients expect. This attention to detail in the cutting and shaping process reflects the overall quality and craftsmanship that goes into the gym flooring, something that dealers can take pride in when presenting the product to their customers.

What Types of Surface Treatments Are Available, and Are They Slip-Resistant?

When selecting rubber gym flooring, the surface treatment is not just a final touch; it’s a critical feature that contributes to the safety and functionality of the flooring. Manufacturers offer a variety of surface treatments to enhance the performance of gym floors, with slip resistance being a top priority.

Options for surface treatments include textured finishes that provide extra grip, even when the surface is wet from sweat or cleaning. These treatments are integral to the flooring and are designed to maintain their slip-resistant qualities throughout the product’s life. From fine granular textures to more pronounced patterns, the level of slip resistance can be tailored to the activities of the space, ensuring athletes can work out with confidence and reduce the risk of slips and falls.

Are There Additional Coatings for Hygiene or Protection?

In today’s world, hygiene is more important than ever, especially in high-traffic gym environments. To address this, some rubber gym floors come with antimicrobial coatings that inhibit the growth of bacteria and mold, contributing to a cleaner and healthier workout environment. These coatings are durable, non-toxic, and do not wear away with regular cleaning, ensuring long-lasting protection.

Beyond antimicrobial properties, protective coatings can also be applied to resist stains and make the cleaning process more manageable. These coatings help to preserve the appearance of the flooring and can extend its lifespan by protecting against spills and abrasive dirt.

Are the Surfaces Treated for UV Resistance?

Exposure to UV light can be a concern, especially for facilities with ample natural light or outdoor workout areas. To combat the effects of UV radiation, such as color fading and material degradation, manufacturers can apply UV-resistant coatings to the rubber gym flooring. These coatings are designed to reflect UV rays and provide a shield that keeps the flooring looking new for years.

Adding UV-resistant treatments is particularly beneficial for gym spaces that want to maintain a vibrant, brand-aligned look without worrying about the sun’s effects on their flooring. It’s an extra layer of assurance that the aesthetic appeal of the gym floor remains intact, even in sun-soaked environments.

Indoor vs. Outdoor Rubber Flooring: What’s the Difference?

Indoor Rubber Flooring:

Indoor rubber flooring is often designed with comfort and durability in mind and is suitable for environments such as gyms, retail spaces, and even residential areas. Indoor rubber flooring is designed with a balance of softness underfoot and the toughness needed to cope with large amounts of foot traffic and equipment. The surface of indoor rubber flooring is usually smooth and not exposed to the elements, so they don’t require the same UV protection as outdoor flooring.

Another critical feature of indoor rubber flooring is its ability to promote the overall hygiene of a space. These floors are treated with an antimicrobial finish that makes them easier to clean and maintain, ensuring a healthier environment for indoor activities.

Outdoor Rubber Flooring:

On the other hand, outdoor rubber flooring is manufactured to withstand the harsh conditions of the outdoor environment. This includes resistance to extreme temperatures, UV rays, and moisture. Outdoor rubber flooring is typically thicker and has a more robust surface texture, providing excellent durability and slip resistance even in wet conditions.

UV resistance is an important feature of outdoor rubber flooring. This material is treated to prevent cracking, fading, or deterioration when exposed to sunlight. Additionally, outdoor rubber flooring is designed to be porous, allowing water to drain, preventing water from pooling on the surface, and reducing the risk of slipping.

What rubber flooring is available for outdoor use?

When choosing rubber flooring for outdoor use, it is essential to select products that are specifically labeled for outdoor or all-weather use. These products are made from rubber compounds formulated to withstand environmental factors such as UV rays, temperature fluctuations, and moisture.

Outdoor rubber flooring comes in various forms, including interlocking and rubber tiles. Interlocking tiles are trendy in outdoor spaces due to their ease of installation and drainage capabilities. They can be used around playgrounds, patios, and pools, providing a safe and durable surface that stands up to the wear and tear of outdoor activities.

In conclusion, the main difference between indoor and outdoor rubber flooring is their design and material composition, which are tailored to meet the specific needs of a particular environment. When used outdoors, the key is to choose rubber flooring that can withstand the elements to ensure longevity and performance in all weather conditions.

What Specific Standards Do Products Meet in Terms of Quality Control?

Quality control is the backbone of manufacturing rubber gym flooring, ensuring that every product meets and exceeds industry standards and customer expectations. Manufacturers adhere to a variety of specific measures that cover everything from material composition to environmental impact.

For instance, many rubber gym flooring products comply with ASTM International standards, which provide guidelines for performance and safety. These standards ensure the flooring can handle the expected load and traffic without compromising comfort or safety. Additionally, products may also meet ISO quality standards, which include rigorous testing for durability and longevity.

Environmental standards are also a crucial part of quality control, with certifications like the FloorScore® certification for indoor air quality being sought after. This ensures that the flooring contributes to a healthier indoor environment, free from harmful emissions.

How Is Dimensional Tolerance Ensured During Production?

Maintaining dimensional tolerance – the permissible limit of variation in a physical dimension of a material – is critical in the production of rubber gym flooring. To ensure that each tile or roll adheres to the specified measurements, manufacturers use precision cutting technology during the production process.

Computer Numerical Control (CNC) machines are calibrated to cut precisely. At the same time, ongoing measurements and adjustments are made to account for any potential material expansion or contraction during the curing process. This meticulous attention to detail guarantees that the final product will fit perfectly in the designated space, ensuring a professional and seamless installation.

How Are Wear and Pressure Testing Conducted on the Products? What Are the Standards?

Wear and pressure testing are vital to predict how a rubber gym floor will hold up over time. Manufacturers conduct these tests using methods such as the Taber Abrasion Test, which measures the wear resistance of the surface layer, and the Puncture Resistance Test, which determines the material’s ability to withstand heavy and sharp objects.

Pressure testing often involves subjecting the flooring to weights and forces that exceed normal usage levels to ensure that it can withstand extreme conditions without failing. The results from these tests must meet or surpass the standards set by organizations such as the American Society for Testing and Materials (ASTM).

By meeting these stringent testing standards, manufacturers can confidently assert the durability and resilience of their rubber gym flooring, providing you with a product that you can trust for its quality and endurance.

In conclusion, the journey of creating rubber gym flooring is one of precision, customization, and stringent quality control. From selecting and purifying recycled rubber to the final touches of surface treatments and UV resistance, manufacturers are committed to delivering a product that is not only durable and functional but also safe and suited to the specific needs of both indoor and outdoor environments.

With advanced technology and adherence to rigorous standards, you can be confident that the rubber gym flooring you provide to your clients is of the highest caliber, designed to withstand the rigors of any fitness activity while supporting the well-being of users and the planet. As we’ve explored the production process, it’s clear that every step is taken with the utmost care to ensure that the final product contributes positively to any fitness space, making it a smart and reliable choice for dealers and end-users alike.