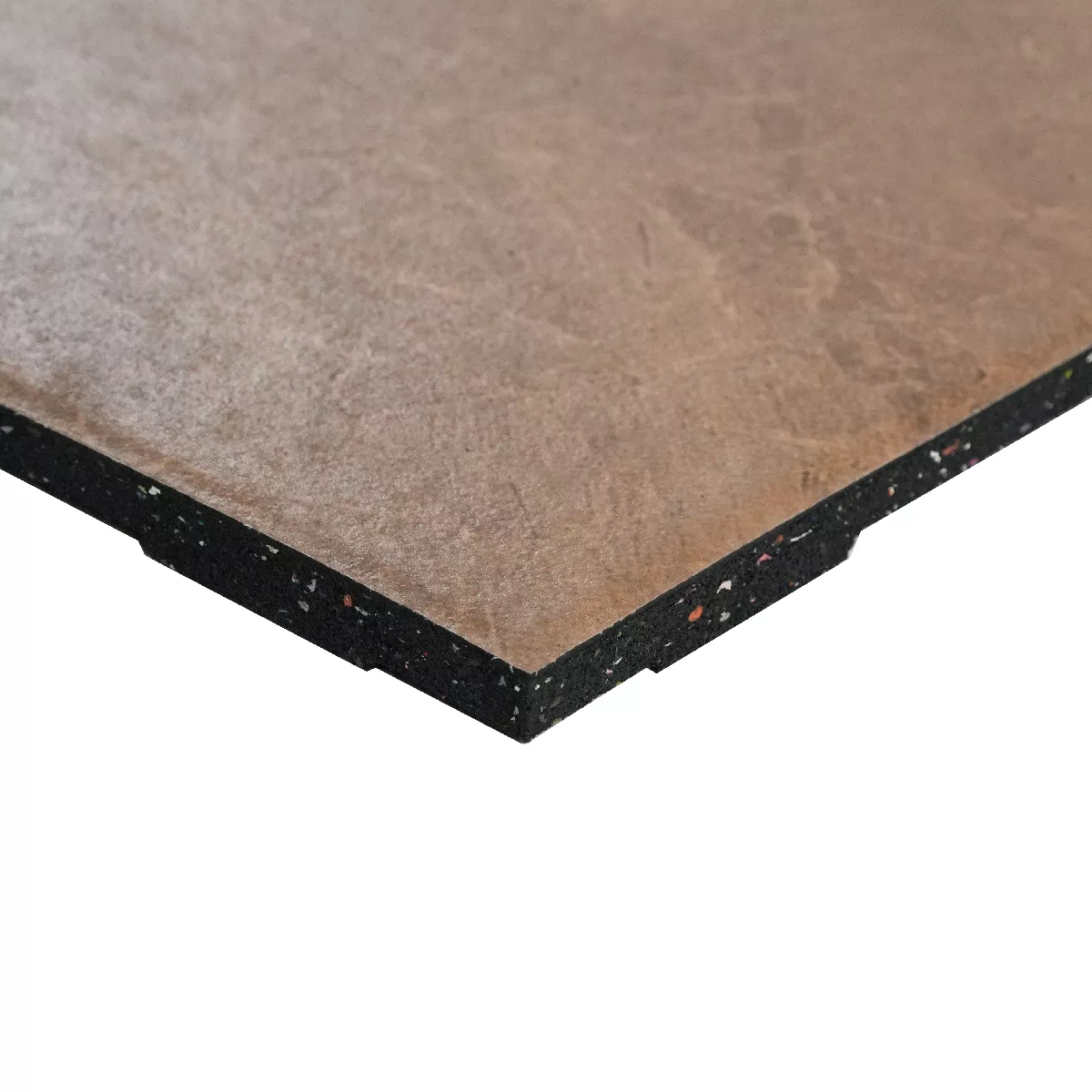

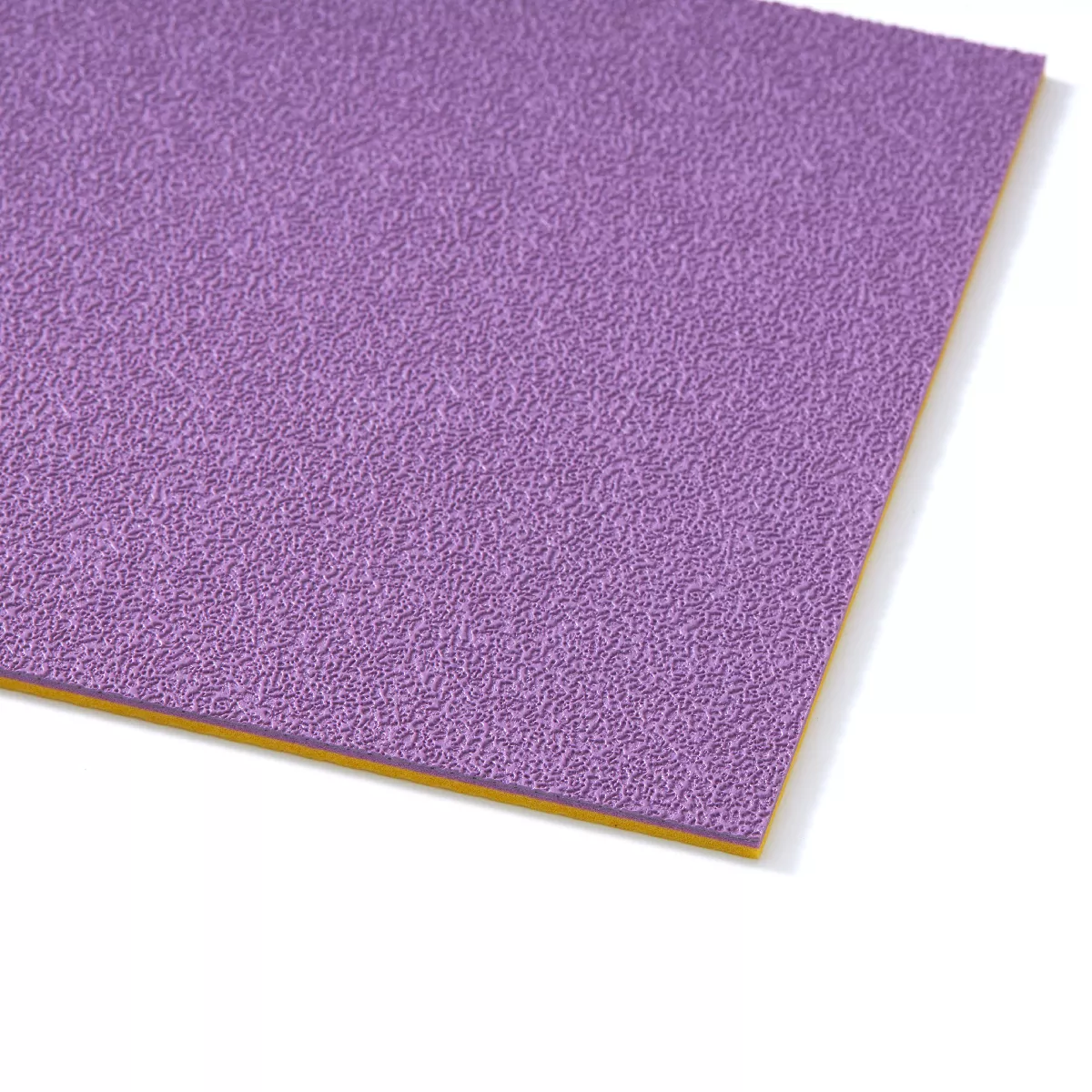

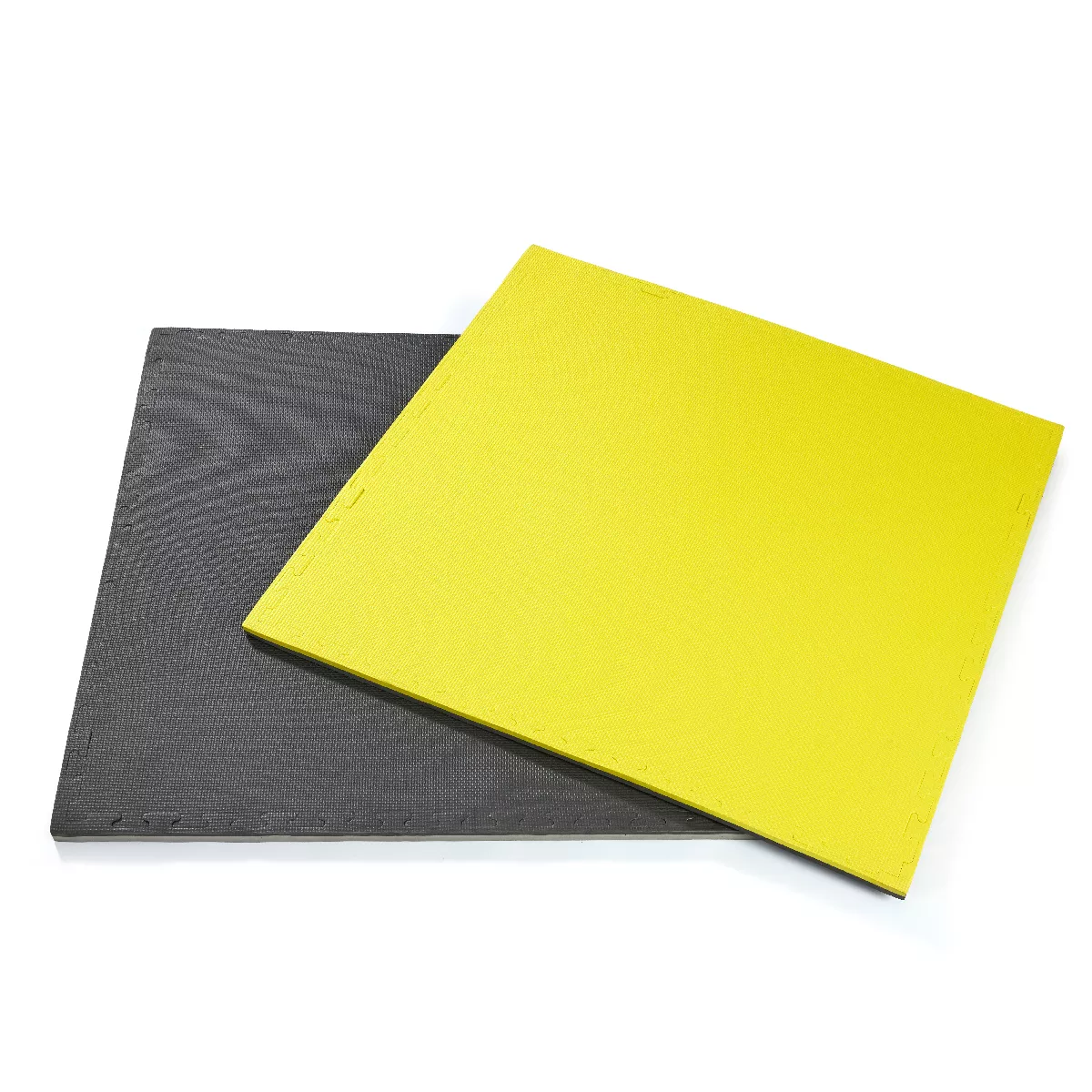

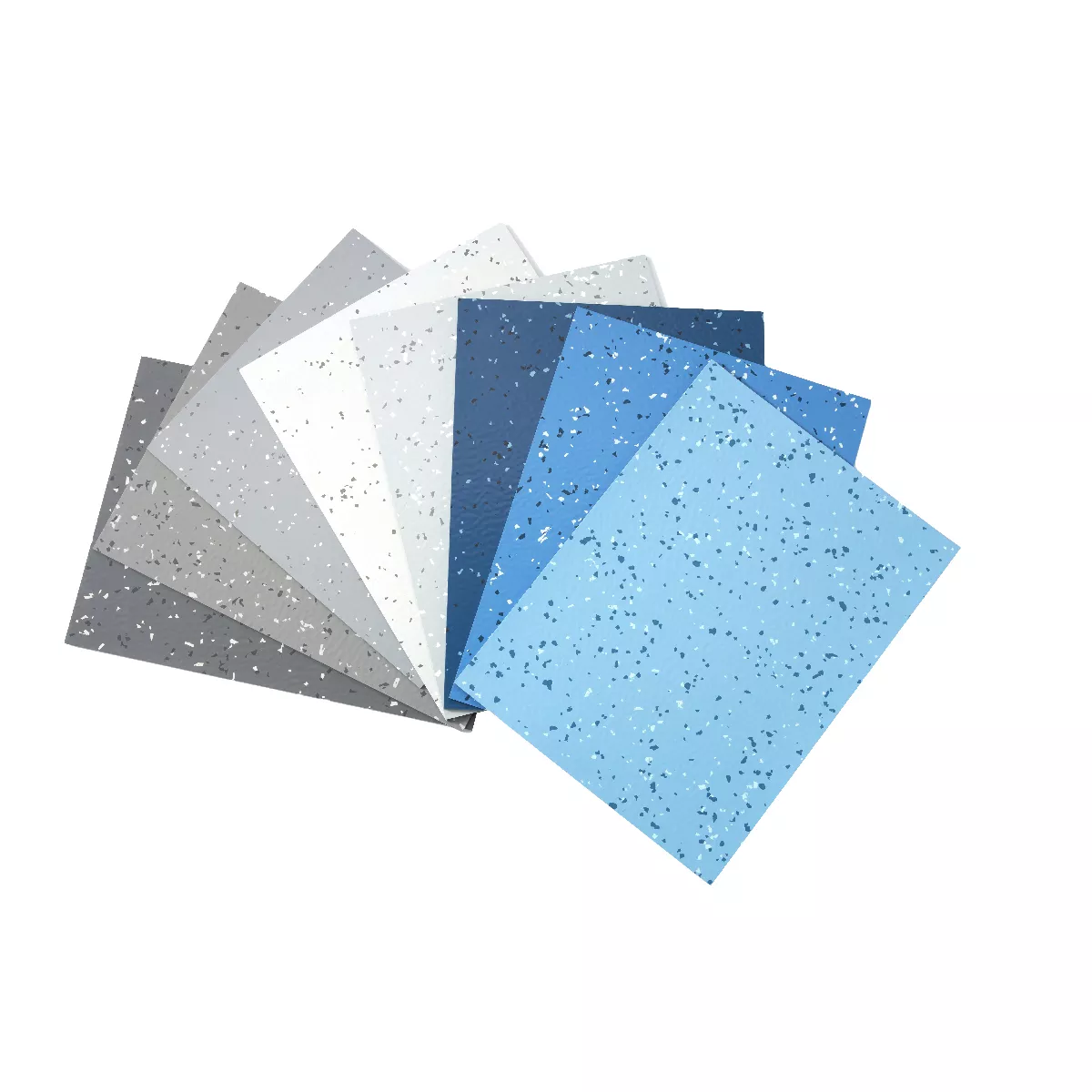

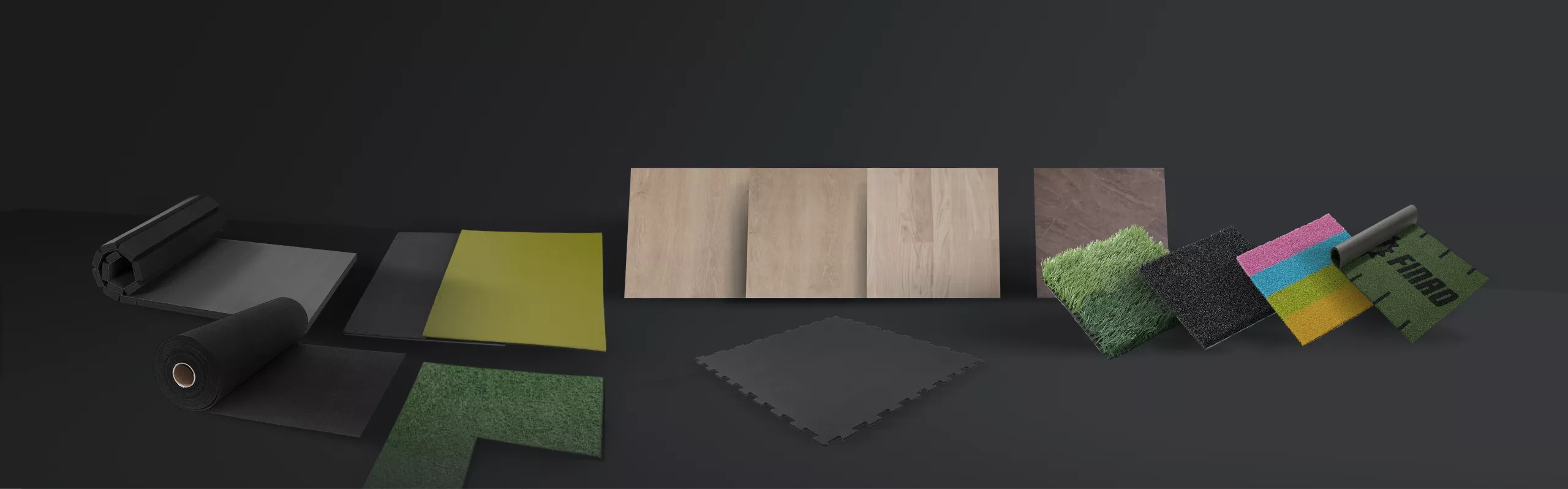

We Make it Easy to Get Fitness and Sports Floor from China Factory

You need more than just fitness and sport floor, you need a manufacturer who has been in the field for 13 years to build your brand and grow your profits. Let MF floor help you achieve business success.