Embarking to find the quintessential rubber gym floor manufacturer in a bustling market can often seem like a Herculean task. As a decision-maker, your mission is profound; you are searching for a manufacturer transcending the conventional realms of mere production. You seek a steadfast partner synonymous with unwavering quality, reasonable pricing, punctual delivery schedules, and robust after-sales assurances.

In this meticulously curated guide, we aim to bestow upon you insights of unparalleled practicality, designed with precision to facilitate the discovery of a manufacturer who emerges as a valuable ally in your business odyssey. Together, we will traverse the critical landscapes of quality, customization, innovation, and after-sales support, illuminating the pathways to effectively evaluate and set your expectations from a rubber gym floor manufacturer.

So, let’s embark on this enlightening journey, equipping you with the essential arsenal of knowledge and confidence, enabling you to unveil a manufacturer who not only aligns with but triumphantly surpasses your expectations, ensuring that the foundations of your fitness sanctuary resonate with an aura of quality and exceptional brilliance.

How Does a Rubber Gym Floor Manufacturer Ensure the Quality of Their Products?

Quality assurance is a paramount factor distinguishing an ordinary rubber gym floor manufacturer from a remarkable one. It’s the invisible thread woven into the products’ fabric, ensuring they stand resilient, functional, and aesthetically pleasing over Time. But how does a manufacturer ensure that the quality of their rubber gym floors is uncompromised and consistently high? Let’s explore this crucial aspect.

Dive into the Quality Control Processes

A dedicated rubber gym floor manufacturer employs meticulous quality control processes to ensure that each square foot of flooring meets a high standard of excellence. From the initial selection of materials to the final inspection, every stage is scrutinized.

Manufacturers often start by sourcing high-quality raw materials, ensuring that the foundation of the flooring is robust. The manufacturing process is a ballet of precision and care, where technology and craftsmanship intertwine to create products that resonate with durability and functionality.

Post-production tests and inspections ensure the flooring withstands various stress factors such as wear, tear, and environmental conditions. This rigorous quality control process ensures that the final product delivered to your fitness center is exceptional.

Certifications and Industry Standards to Look For

Certifications and adherence to industry standards are the badges of honor for rubber gym floor manufacturers. They are a testament to a manufacturer’s commitment to delivering products that meet recognized standards of quality, safety, and performance.

Look for manufacturers who proudly display certifications that attest to the non-toxicity, fire resistance, and anti-slip properties of their flooring. Compliance with industry regulations and standards, such as ISO certifications, is also a strong indicator of a manufacturer’s dedication to quality assurance.

These certifications are not just symbols; they are a promise and a guarantee that the manufacturer has invested Time, technology, and thought into creating products that stand up to global standards of excellence.

In conclusion, a rubber gym floor manufacturer ensures the quality of their products through rigorous quality control processes and adherence to respected industry certifications and standards. These elements combined weave a tapestry of trust, reliability, and assurance in the quality of the products you choose for your fitness center.

What are the most critical steps in the manufacturing process of rubber gym flooring?

Navigating the intricate pathways of manufacturing rubber gym flooring reveals a meticulous symphony of processes and decisions, each playing a pivotal role in the birth of a resilient and durable floor. Let’s embark on a detailed exploration of this journey, focusing on selecting high-quality raw materials and the crucial vulcanization process to provide a clearer understanding of what makes rubber gym flooring stand out in terms of quality and performance.

Selecting High-Quality Raw Materials

The foundation of exceptional rubber gym flooring lies in the selection of premium raw materials. High-quality rubber, whether natural, synthetic, or recycled, is paramount. But how do you discern the quality of the raw materials?

1. Source and Origin: Consider where the materials are sourced. Ethically sourced and environmentally friendly materials often translate to higher quality.

2. Material Consistency: Look for manufacturers who prioritize consistency in their raw materials, ensuring that the rubber’s performance characteristics meet specific standards.

3. Material Purity: The purity of the rubber and the absence of contaminants or fillers are essential for the durability and performance of the final product.

Understanding the Vulcanization Process

Vulcanization is a transformative process in the manufacturing of rubber gym flooring. It involves heating the rubber material, mixed with curing agents such as sulfur, under pressure to create cross-links between the rubber molecules. This process enhances the rubber’s elasticity, resilience, and durability, making it more suitable for rigorous and demanding fitness environments.

1. Temperature and Pressure Control: Precise control over the temperature and pressure during vulcanization is crucial for achieving the desired flooring characteristics.

2. Curing Time: The duration of the vulcanization process affects the density and durability of the rubber. An optimized curing time ensures that the flooring achieves the right balance of hardness and flexibility.

3. Quality Checks: Post-vulcanization, the flooring should undergo stringent quality checks to ensure that the process has been successful and that the flooring meets the necessary performance criteria.

In conclusion, the choice of high-quality raw materials and a meticulously executed vulcanization process are instrumental in the manufacturing of superior rubber gym flooring. Understanding these aspects provides a more profound insight into the considerations and procedures contributing to creating flooring that meets and exceeds the expectations of durability, performance, and quality in a fitness environment.

What are the customization options when working with rubber gym floor manufacturers?

Cooperation with rubber gym floor manufacturers opens up a field of possibilities to customize the floor to meet the unique needs and aesthetics of your buyers. Customization is a powerful tool that allows your buyers to inject personality, brand identity, and specific features into the gym floor. Let us explore various customization options to transform your customer’s fitness space into a customized environment that resonates with his vision and brand spirit.

Explore color, thickness, and size changes

The first aspect to be studied in depth is the physical appearance and specifications of the floor. Manufacturers usually offer a range of colors, allowing you to choose a tone consistent with your brand color or the atmosphere required for your fitness space.

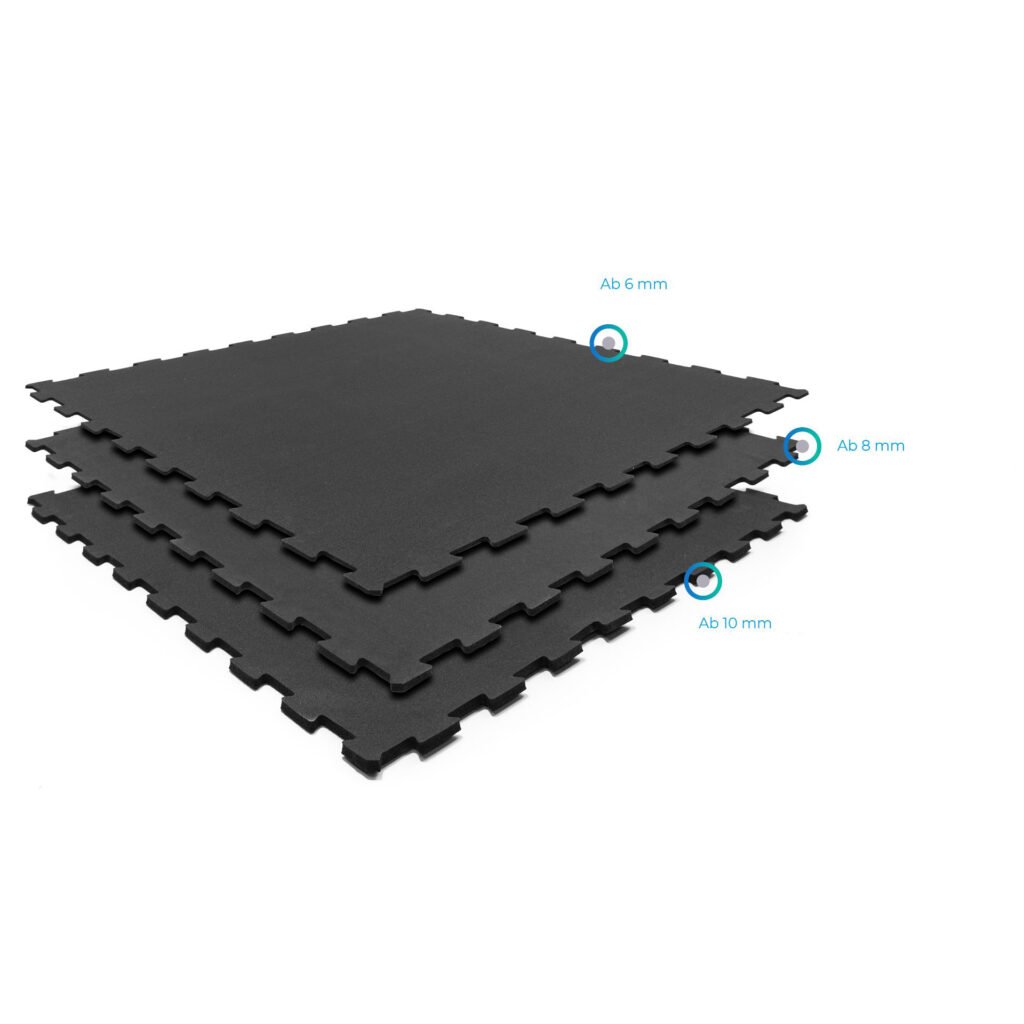

Thickness is another crucial aspect. Depending on the activities and equipment type held by your gym, you can choose different thickness levels to ensure correct support, elasticity, and impact absorption.

Size variations and formats, such as tiles or rolls, provide flexibility in installation and design. According to buyers’ needs, you can choose a size that minimizes waste, fits a specific area, or promotes a particular pattern of design or layout.

Possibility of logo and design imprint

Customized imprints, such as logos and designs, allow your buyers to inject a strong brand identity into the floor. This is an opportunity to make the bed a canvas, speak his brand language, enhance visual appeal, and create a unique fitness center.

The manufacturer that provides this customization option will work closely with you to accurately replicate the logo, pattern, or any other design element to ensure clarity, durability, and visual impact. This level of customization helps to create a prominent space and provide a unique and branded exercise environment.

In short, working with rubber gym floor manufacturers provides a wealth of customization options that enable you to create a fitness space that is not only functional and durable but also truly reflects your brand and vision. These customization possibilities allow for a harmonious mix of practicality and aesthetics, contributing to a more attractive and inspiring fitness environment.

What Innovations Are Rubber Gym Floor Manufacturers Bringing to the Market?

In a world where innovation is the driving force behind enhancement and improvement, rubber gym floor manufacturers are still in the process. They continuously strive to infuse cutting-edge innovations into their products, aiming to revolutionize the fitness flooring landscape. These innovations are not merely about keeping up with trends; they are about elevating the functionality, aesthetics, and overall user experience of fitness spaces. Let’s uncover the latest innovations that are reshaping the realm of rubber gym flooring.

Latest Trends and Technologies in Rubber Gym Flooring

Manufacturers are embracing new technologies and materials to enhance the durability, resilience, and eco-friendliness of rubber gym floors. For instance, advancements in material engineering have led to the creation of bases that are more resistant to wear and tear, ensuring longevity despite heavy usage.

Another trend is the integration of antimicrobial technologies. In a fitness environment where hygiene is paramount, floors that resist bacteria and microbes are a significant asset, contributing to a cleaner and healthier space.

Moreover, there’s a growing emphasis on sustainability. Innovations are steering towards the utilization of recycled materials and the development of flooring solutions that are more environmentally friendly, aligning with global sustainability goals.

How Innovations Enhance the Functionality and Aesthetics of Fitness Spaces?

Innovations in rubber gym flooring play a pivotal role in enhancing the functionality of fitness spaces. Enhanced durability means the flooring can withstand the rigorous demands of a gym environment, from heavy equipment to high foot traffic.

Aesthetic enhancements are also notable. With a broader array of design and customization options, gym owners can create visually appealing spaces, aligning with modern design trends and contributing to an inviting and inspiring workout environment.

Furthermore, innovative flooring solutions contribute to improved acoustics and comfort. Floors that absorb sound and impact better contribute to a quieter and more comfortable environment, enhancing the overall workout experience.

In conclusion, the innovations brought forth by rubber gym floor manufacturers are instrumental in pushing the boundaries of what’s possible in fitness flooring. By embracing these advancements, fitness centers can benefit from flooring that is not only robust and functional but also aesthetically pleasing and aligned with modern needs and expectations.

How Does the Rubber Gym Floor Manufacturer Test the Durability?

Durability is the bedrock of rubber gym flooring. It’s the silent guardian that ensures the flooring withstands the relentless demands of a bustling fitness environment, from the constant pounding of feet to the weight of heavy equipment. But how do manufacturers ensure their rubber gym flooring embodies this essential attribute? Let’s delve into the meticulous processes that test and affirm the durability of rubber gym floors.

Unveiling the Testing Processes for Durability

Manufacturers employ a battery of tests to ascertain the durability of their rubber gym flooring. These tests are designed to mimic the real-world challenges that the floors will face, ensuring they are up to the task.

1. Impact Resistance: Floors are subjected to impacts that simulate the dropping of weights and heavy equipment usage. This test is crucial to understand how the flooring responds to forceful contact and whether it can maintain its integrity over Time.

2. Wear and Tear: Testing for wear and tear involves subjecting the flooring to conditions that replicate high foot traffic and regular usage. It helps evaluate how the flooring withstands daily demands and whether it retains its appearance and functionality.

3. Environmental Resistance: The flooring is also tested against various environmental factors such as moisture, heat, and chemicals. These tests ensure the flooring can endure different conditions without losing its essential properties.

Importance of Durability in Gym Flooring Selection

Durability is a non-negotiable attribute when selecting gym flooring. It’s a direct contributor to the longevity of the floor and its ability to maintain a high performance level over Time.

A durable floor minimizes the need for frequent repairs and replacements, contributing to cost-effectiveness and uninterrupted operation of the fitness center. It also ensures that the floor remains a safe and reliable exercise platform, supporting the users’ activities without compromise.

Moreover, durability also influences the aesthetic retention of the floor, ensuring that it continues to look and feel appealing, contributing positively to the overall ambiance of the fitness space.

In conclusion, testing for durability is a rigorous process that rubber gym floor manufacturers undertake to ensure their products stand resilient against the multifaceted challenges of a fitness environment. It’s a critical consideration that influences the performance, maintenance, and longevity of the flooring in a fitness center.

How Can Rubber Gym Flooring Improve the Acoustics of Your Fitness Space?

In the dynamic environment of a fitness center, where the rhythmic thuds of weights, the swift movements of athletes, and the vibrant beats of music converge, acoustics play a pivotal role in defining the user experience. Rubber gym flooring emerges as a silent hero in this aspect, significantly contributing to the acoustic enhancement of the fitness space. But how exactly does rubber gym flooring weave its magic in improving the acoustics? Let’s explore this auditory aspect.

The Acoustic Benefits of Choosing Rubber Gym Flooring

Rubber gym flooring inherently possesses acoustic-friendly properties. Its elastic nature allows it to absorb sound and vibrations, reducing noise transmission through the floor. This is particularly beneficial in a gym where dropping weights, the clattering of machines, and foot traffic are expected.

The absorption of sound helps in minimizing echo and background noise, creating a more focused and less disruptive environment. It allows for more transparent communication, whether in group classes or one-on-one training sessions and contributes to a more enjoyable audio experience, whether it’s the instructor’s voice or the background music.

Ways Manufacturers Optimize Flooring for Better Acoustics

Manufacturers meticulously engineer rubber gym flooring with a focus on enhancing its acoustic properties. The density and thickness of the flooring are optimized to maximize sound absorption, ensuring that it effectively dampens noise and vibrations.

Some manufacturers also incorporate specific design features or additional materials to enhance the flooring’s acoustic properties. For instance, they might use specialized underlays or include textured surfaces that contribute to sound absorption.

Moreover, manufacturers also consider the installation process and provide guidelines to ensure that the flooring is laid out in a manner that maximizes its acoustic benefits, such as recommending specific adhesives or installation techniques.

In conclusion, rubber gym flooring acts as a powerful acoustic ally in a fitness environment, absorbing and minimizing noise and vibrations, thus enhancing the overall auditory experience. Choosing flooring specifically engineered for acoustic optimization can make a significant difference, contributing to a more comfortable, focused, and enjoyable fitness space.

What Should You Look for in a Warranty from a Rubber Gym Floor Manufacturer?

A warranty is more than just a piece of paper; it’s a promise, a seal of confidence, and a pivotal aspect to consider when choosing a rubber gym floor manufacturer. It speaks volumes about the manufacturer’s faith in their products and commitment to customer satisfaction. But what elements make a warranty solid and reliable, and why is it crucial in your selection process? Let’s unravel the intricacies of contracts in rubber gym flooring.

Key Aspects to Consider in a Warranty

1. Coverage: A comprehensive warranty should cover various aspects such as material defects, artistry errors, and performance issues. It should provide clear information on what is included and excluded from the coverage.

2. Duration: The warranty length is also crucial. A more extended warranty period often signifies the manufacturer’s confidence in the product’s durability and longevity.

3. Terms and Conditions: Pay close attention to the terms and conditions. Look for any clauses that might be restrictive or situations that might void the warranty.

4. Claim Process: A good warranty should come with a straightforward and hassle-free claim process. It should provide clear instructions on how to make a claim, what documentation is required, and what steps will follow a claim submission.

5. Customer Support: Consider the level of customer support that accompanies the warranty. Reliable customer service that is readily available to answer queries and assist with claims adds significant value to the contract.

The Significance of a Strong Warranty in Your Selection Process

A robust warranty is a powerful tool for safeguarding your investment. It provides a safety net, ensuring that you are protected against unforeseen issues related to the flooring’s quality and performance.

Having a solid warranty also speaks to the manufacturer’s credibility and reliability. It reflects their confidence in their products and commitment to fulfilling their quality promises.

Moreover, a warranty can also be a decisive factor in choosing different manufacturers. It adds an extra layer of assurance, providing peace of mind that the manufacturer will support you in the event of any issues or discrepancies with the flooring.

In conclusion, a warranty is a significant aspect to scrutinize when selecting a rubber gym floor manufacturer. It should be comprehensive, customer-friendly, and reflective of the manufacturer’s confidence in the durability and quality of their products. A strong warranty acts as a protective shield, ensuring that your investment in rubber gym flooring is secure and supported throughout its lifecycle.

What Are the Common Mistakes to Avoid When Choosing a Rubber Gym Floor Manufacturer?

Choosing a rubber gym floor manufacturer is a significant decision, one that influences the quality, functionality, and aesthetics of your fitness space. However, the journey to making this choice is sprinkled with pitfalls that could divert you from finding the best fit. Awareness of these common mistakes is the first step towards avoiding them, enabling you to make a decision that aligns with your needs and expectations. Let’s explore these common mistakes and arm you with tips to navigate around them.

Identifying Potential Pitfalls in the Selection Process

1. Overlooking Quality for Cost: While budget considerations are crucial, prioritizing cost over quality could compromise durability, performance, and overall satisfaction.

2. Neglecting Research: Failing to conduct thorough Research and due diligence on the manufacturer’s reputation, expertise, and customer feedback could lead to uninformed decisions.

3. Ignoring Customization Options: Overlooking the manufacturer’s ability to offer customization in design, color, and size might limit your ability to create a space that aligns with your vision.

4. Disregarding the Importance of Warranties: Not giving due importance to the warranty, its coverage, and terms can leave you vulnerable to potential issues without adequate protection.

Tips to Make a Well-Informed Decision

1. Balance Quality and Cost: Aim for a balance where you receive value for your investment, ensuring that the chosen flooring meets quality standards within your budget.

2. Conduct Comprehensive Research: Invest Time in researching different manufacturers, exploring their portfolios, customer reviews, and industry reputation to gather a well-rounded perspective.

3. Explore Customization Possibilities: Engage with manufacturers to explore the extent of customization they offer, ensuring that the final product will resonate with your specific needs and aesthetics.

4. Scrutinize Warranties: Carefully examine the warranties, understanding the coverage, duration, and terms to ensure robust protection against potential issues.

5. Seek Professional Guidance: Don’t hesitate to seek advice from industry experts or professionals with experience in gym flooring selection to gain insights that can guide your decision.

In conclusion, avoiding common mistakes in choosing a rubber gym floor manufacturer involves a thoughtful approach, comprehensive Research, and careful consideration of various factors such as quality, customization, and warranties.

Armed with these insights, you can navigate the selection process with clarity and confidence, ensuring that your choice aligns with your expectations and contributes positively to the success of your fitness space.