Have you ever wondered what makes rubber gym floors so durable and resilient? Well, it’s like a superhero transformation story, and the hero in this tale is vulcanized rubber. Imagine natural rubber as a superhero in its ordinary life; it is helpful but limited. Now, enter the extraordinary world of Vulcanization, a process that empowers rubber with enhanced strength, elasticity, and resistance, preparing it for the challenges in the high-impact environment of a gym.

Vulcanization is not just a technical term; it’s the secret sauce that brings rubber gym floors to life, ensuring they withstand the test of time, usage, and elements. In the heart of this process lies a metamorphosis, where rubber evolves to meet the demanding needs of a fitness haven. But why is Vulcanization so crucial in the production journey of rubber gym floors? Let’s unravel this mystery together, exploring the wonders of Vulcanization and discovering why it’s an indispensable chapter in the life story of rubber gym floors. Join me on this enlightening journey, and let’s dive deep into the world of vulcanized rubber gym floors!

Why is Vulcanization Essential in the Production of Rubber Gym Floors?

Vulcanization is like the secret initiation ritual that rubber must undergo to unlock its full potential, especially when conquering the demanding terrains of gym floors. But why is this process so indispensable? Let’s dive into the transformative journey that Vulcanization offers to rubber, preparing it for the robust life in a gym.

Firstly, Vulcanization is like a rite of passage that amplifies rubber’s natural abilities. It’s about taking the innate qualities of rubber – its flexibility and softness – and elevating them to new heights of toughness and resilience. This is crucial because gym floors aren’t just about soft landings; they must endure the relentless pounding from weights, the constant scuffle of feet, and the abrasive interaction with various fitness equipment.

Vulcanization also plays the role of a protective guardian. It enhances rubber’s resistance against myriad adversaries such as heat, chemicals, and electrical currents. In a challenging gym environment, where the floor is exposed to sweat, cleaning agents, and varying temperatures, this resistance becomes a superpower, ensuring longevity and maintaining aesthetics.

Moreover, Vulcanization ensures consistency and uniformity in the rubber, creating a harmonious surface that is reliable and steadfast. In the dynamic world of fitness, where precision and stability are paramount, having a floor that offers consistent performance is a non-negotiable asset.

In the grand theatre of gym flooring, vulcanized rubber is the star performer, delivering a powerful and enduring performance. It’s about ensuring that the gym floor is not just a surface but a steadfast partner in the fitness journey, capable of withstanding the trials and tribulations of rigorous workouts, ensuring a stage that is always set for excellence. So, Vulcanization is not just a process; it’s the crafting of a champion, ready to triumph in the demanding arena of gym flooring.

What Makes Vulcanized Rubber Different from Natural Rubber?

In the vast universe of materials, rubber holds a special place with its unique characteristics. But not all rubber is created equal. Let’s embark on a journey to explore the differences between natural rubber and its evolved counterpart, vulcanized rubber, and uncover why the latter stands out as a superior choice in various applications, especially in gym flooring.

Why is Natural Rubber Not Very Useful on its Own?

Natural rubber is like raw talent. It has intrinsic qualities such as elasticity and softness, making it quite versatile in various applications. However, rubber also exhibits specific vulnerabilities when left in its natural state. It tends to be sensitive to temperature variations, prone to wear and tear, and susceptible to aging and chemical attacks.

In the challenging environment of a gym, these vulnerabilities could translate to a floor that wears out quickly, loses its appeal, and fails to provide the necessary resilience and support over time.

How Does Vulcanization Enhance Rubber?

Vulcanization acts like a mentor to the natural rubber, guiding it through a transformative process that enhances its strengths and mitigates its weaknesses. Rubber undergoes a chemical transformation through Vulcanization, where sulfur bridges are introduced into the polymer chains. This strengthens the rubber and makes it more resistant to wear, heat, and other adverse conditions.

In gym flooring, vulcanized rubber emerges as a clear winner. It brings to the table enhanced durability, ensuring that the floor remains in prime condition despite the heavy foot traffic and rigorous activities. Its improved heat resistance maintains its integrity and appearance even under varying temperature conditions. Moreover, vulcanized rubber offers a more consistent and reliable surface, ensuring that it meets the high-performance demands of a fitness environment.

In conclusion, while natural rubber brings innate flexibility and softness, Vulcanization elevates these qualities, preparing rubber to meet demanding applications’ demands with enhanced resilience, consistency, and durability. It’s like witnessing the transformation of an amateur into a seasoned performer, ready to shine on the demanding stage of gym flooring.

How Does Vulcanization Enhance the Durability of Rubber Gym Floors?

Vulcanization is like the guardian angel of rubber gym floors, a protective force that arms them with an extraordinary shield of durability and resilience. But how exactly does this magical process bestow rubber with such formidable qualities, enabling it to triumph in the challenging arena of gym flooring? Let’s unravel this mystery and explore Vulcanization’s transformative influence on rubber gym floors’ longevity and toughness.

Imagine Vulcanization as a rigorous training camp where the rubber is conditioned, strengthened, and empowered. In this process, rubber is exposed to heat and sulfur, a transformative combination that restructures its molecular architecture. This metamorphosis enhances the rubber’s physical properties, making it more challenging, flexible, and incredibly resistant to wear and tear.

In the high-impact world of gym floors, durability is king. Floors must withstand a relentless onslaught of activities, from the pounding of heavyweights to the constant shuffle of feet. With its enhanced toughness, Vulcanized rubber stands steadfast against these challenges, ensuring a surface that maintains its integrity, appearance, and performance over time.

Moreover, vulcanization arms rubber with remarkable resistance to various environmental adversaries such as extreme temperatures and moisture. This means that vulcanized rubber gym floors are less likely to succumb to the damaging effects of heat, cold, or humidity, ensuring a longer lifespan and reduced maintenance needs.

In essence, Vulcanization is the hero behind the scenes, silently enhancing the rubber’s capabilities, preparing it to face and conquer the rigorous demands of gym flooring with unmatched durability and resilience. It’s the secret ingredient that ensures rubber gym floors survive and thrive in their challenging, high-impact environments, promising a performance that stands the test of time and toughness.

What are the Technical Aspects of the Vulcanization Process?

Vulcanization is a symphony of science and precision, where various technical elements combine to compose the enhanced rubber masterpiece. It’s a meticulous process governed by specific parameters and controls, ensuring that the rubber evolves into a material of superior quality and resilience. Let’s navigate the technical landscapes of Vulcanization, exploring the intricate details that define this transformative journey.

How are Temperature and Pressure Controlled During Vulcanization?

Temperature and pressure serve as the conductors of the vulcanization orchestra, guiding the performance to ensure harmony and excellence. These two variables are carefully calibrated and controlled to facilitate the optimal environment for rubber transformation.

Temperature is a crucial maestro in this process. It’s meticulously managed to ensure the heat is sufficient to activate the sulfur and initiate the cross-linking process within the rubber polymers. Too much heat and the rubber might suffer degradation; too little, and the Vulcanization may be incomplete. Thus, a precise temperature is maintained to ensure that the vulcanization process unfolds accurately and effectively.

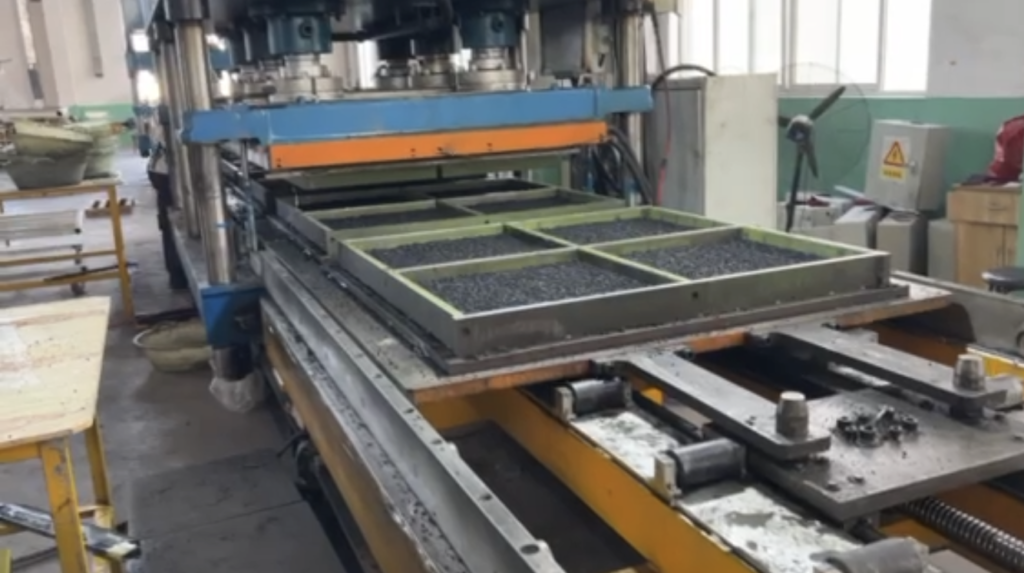

Pressure, the co-conductor, plays an equally pivotal role. It ensures the rubber maintains uniform contact with the heat source, facilitating an even and consistent vulcanization process. The pressure also aids in achieving the desired shape and thickness of the rubber products, ensuring that they meet the specific requirements and standards.

In the grand performance of Vulcanization, temperature and pressure work in concert, each playing their part to perfection. Their precise control and management are essential to the process’s success, influencing the vulcanized rubber’s quality, consistency, and reliability. Together, they orchestrate a process that allows the rubber to transcend its natural limitations, evolving into a material that resonates with durability, resilience, and excellence, ready to shine in various applications, including the demanding stages of gym flooring.

What are the challenges in the vulcanization process?

Although Vulcanization is the guardian of rubber change, it has its trials and tribulations. This is a journey of transformation. The rubber has been enhanced and strengthened, but the road is full of challenges and requires meticulous attention and precise navigation. Let us explore the obstacles that hinder this extraordinary process and how they affect the journey of rubber from its natural state to the miracle of Vulcanization.

One of the most critical challenges is controlling the temperature and pressure throughout the process. Both temperature and pressure are indispensable. The value of the pressure in the production process is fixed, and the temperature can be adjusted. There are slight differences in the temperature and vulcanization time used in rubber gym floors of different thicknesses. These two variables are the pillars of successful Vulcanization. Any inconsistency or deviation in their management may lead to defects in vulcanized rubber, such as uneven hardness, surface defects, or loopholes in the overall durability and performance of the material.

Another challenge lies in the field of materials. Care must be taken in selecting accelerators, activators, and other chemicals used in Vulcanization to ensure compatibility with rubber and promote the effectiveness of the vulcanization process. The wrong choice or proportion of these materials can affect the quality of vulcanized rubber and its applicability to specific applications (such as gym floors).

Environmental considerations also pose challenges. Vulcanization, by its nature, involves heat and the use of various chemicals, raising concerns about energy consumption, emissions, and waste. Ensuring this process is carried out environmentally and complies with regulations and standards is essential to its sustainability and acceptability.

Finally, the search for innovation and improvement is an ongoing challenge. The vulcanization process must evolve and adopt new technologies, materials, and methods to improve efficiency, effectiveness, and environmental friendliness. This requires continuous research, development, and adaptation to meet the changing needs and expectations of the industry, consumers, and regulators.

In short, although Vulcanization is a powerful ally in improving rubber capabilities, it is a process that requires respect, precision, and continuous improvement to overcome its inherent challenges and give full play to its potential to provide rubber materials of excellent quality and performance.

How Does Vulcanization Comply with Industry Standards?

Navigating through the meticulous pathways of Vulcanization, a constant compass guides the journey: compliance with industry standards. These standards act as the guardians of quality, safety, and performance, ensuring that the vulcanized rubber emerges as a product that meets and exceeds the expectations of reliability and excellence.

Let’s explore how Vulcanization aligns with these pivotal benchmarks, ensuring the production of rubber gym floors that resonate with integrity and assurance.

Are the Floors Produced Safe and Non-Toxic After Vulcanization?

Safety and non-toxicity are the cornerstones of industry standards, and Vulcanization pays homage to these principles with utmost dedication. The process is orchestrated to ensure that the resulting rubber floors embody a sanctuary of safety, free from harmful toxins and substances that could compromise the well-being of users.

During Vulcanization, careful consideration is given to selecting accelerators, activators, and other auxiliary agents. The aim is to foster a process that minimizes the risk of residual toxins or the release of harmful substances during the product’s lifecycle. The vulcanized rubber floors are thus curated to be companions of health and fitness, supporting users in their physical pursuits without exposing them to health risks.

Certifications and testing play a pivotal role in validating the safety and non-toxicity of vulcanized rubber floors. Products are subjected to rigorous assessments to verify their compliance with established safety standards, ensuring they are worthy of trust and confidence. These certifications act as badges of assurance, testifying to the product’s adherence to quality and safety benchmarks.

In conclusion, Vulcanization is a process that reveres industry standards, weaving them into the fabric of its procedures and outcomes. It crafts rubber gym floors that stand as ideals of safety and quality, ensuring that they serve as reliable platforms for fitness, well-being, and the pursuit of physical excellence, embodying the essence of industry compliance and user-centric dedication.

How Customizable are Vulcanized Rubber Gym Floors?

Vulcanized rubber gym floors are not just about durability and resilience but also a canvas of creativity and customization. With its transformative prowess, Vulcanization brings possibilities that allow for a delightful design, texture, and functionality diversity. Let’s delve into the artistic and adaptable aspects of vulcanized rubber gym floors, exploring how they can be tailored to meet specific aesthetic and performance visions.

Vulcanization infuses rubber with flexibility beyond its physical attributes, extending into design and aesthetics. It allows for a spectrum of colors, patterns, and designs to be integrated into the gym floors, enabling spaces that resonate with vibrancy, motivation, and thematic elegance. Whether it’s a bold, energetic palette or a subtle, sophisticated hue, vulcanized rubber floors can be customized to echo the desired ambiance and identity of the gym.

Texture and surface finish are another arena where customization shines. Vulcanization facilitates the creation of surfaces that range from smooth and sleek to rugged and robust, each catering to specific needs and activities within the gym. For instance, areas dedicated to yoga or stretching may feature smooth, soft surfaces, while zones marked for weightlifting might boast tougher, more resilient textures. This adaptability ensures that each gym section is optimized for performance, safety, and comfort.

Moreover, vulcanized rubber floors can also be engineered to offer varying hardness and shock absorbency, ensuring that they cater to the diverse impact and support needs of different fitness activities. This customization ensures a floor that is not just a passive surface but an active participant in the fitness journey, adapting and responding to the unique demands of each exercise and user.

In essence, vulcanized rubber gym floors embody a spirit of customization that celebrates diversity, functionality, and aesthetic excellence. They allow for the creation of fitness spaces that are not just practical but also inspirational, ensuring an environment that enhances, supports, and elevates the overall gym experience. Through Vulcanization, rubber gym floors become a harmonious blend of science and art, engineering and creativity, durability and design.

What Innovations are Present in the Vulcanization Process of Rubber Gym Floors?

Innovation is the driving force that propels the vulcanization process into new realms of excellence and efficiency. It’s the wind beneath the wings of Vulcanization, allowing it to soar higher in delivering rubber gym floors that resonate with quality, performance, and sustainability. Let’s explore the landscape of innovation in Vulcanization, uncovering the technological advancements that are revolutionizing the creation of rubber gym floors.

One significant innovation lies in the realm of process optimization. Advanced machinery and automation technologies have streamlined the vulcanization process, enhancing precision, consistency, and productivity. These technological marvels ensure that every square inch of the rubber gym floor is vulcanized to perfection, embodying the pinnacle of quality and performance.

Material innovation also plays a pivotal role. The advent of new accelerators, curing agents, and other chemical components has enriched the vulcanization process. These materials enhance the efficiency of the process and the overall quality of the vulcanized rubber, allowing for gym floors that exhibit superior durability, resilience, and user comfort.

Sustainability is another frontier where innovation shines brightly. New techniques and materials are being embraced that aim to reduce the environmental footprint of the vulcanization process. This includes utilizing eco-friendly materials, energy-efficient operations, and waste reduction strategies, reflecting a commitment to crafting rubber gym floors that are exceptional in performance and kind to our planet.

Innovation also extends to customization and design flexibility. Advanced technologies allow greater precision and variety in rubber gym floor design, texture, and finishing. This enables the creation of visually appealing floors, functionally diverse and uniquely tailored to each gym’s specific needs and aesthetics.

In conclusion, innovation in the vulcanization process is a symphony of advancements that harmonize to enhance rubber gym floors’ quality, efficiency, and sustainability. The catalyst propels Vulcanization towards new horizons of excellence, ensuring that rubber gym floors continue to evolve, improve, and inspire in the dynamic world of fitness flooring.

In the intricate ballet of Vulcanization, science, and innovation dance in perfect harmony, they craft rubber gym floors that resonate with durability, customization, and excellence. Through meticulous processes, thoughtful innovations, and a steadfast commitment to quality, vulcanized rubber gym floors emerge as paragons of resilience and performance.

They stand as silent yet powerful allies in our fitness journeys, embodying a fusion of technological brilliance and practical functionality. In the heart of each vulcanized rubber gym floor lies a saga of transformation, a testament to the remarkable journey of rubber through the crucible of Vulcanization, emerging triumphant and ready to face the rigors of the fitness world with unmatched grace and endurance.