Horse stall mats are essential investments for equine facilities, providing crucial protection for your horses while extending the life of your stable floors. Before purchasing, you need to consider size, thickness, material quality, traction features, and proper installation to ensure you’re getting durable, safe flooring that meets your specific needs.

As someone who’s overseen the production of thousands of rubber flooring solutions, I’ve learned that horse stall mats are much more than simple floor coverings. They’re specialized equipment designed to protect both your horses and your facility investment. The right mat can prevent injuries, reduce joint stress, and create a more hygienic environment, while poor-quality options can lead to premature replacement and potential safety hazards.

When choosing stall mats, remember that not all rubber flooring is created equal. High-density recycled rubber provides excellent durability and impact absorption, while lower-density materials might save money initially but cost more in the long run through faster wear and reduced protection. I always recommend measuring your stalls precisely before ordering, accounting for any unusual corners or features, and considering the specific needs of your horses based on their size, age, and activity level.

Many horse owners I’ve worked with initially focus solely on price, only to discover that investing in quality mats from the beginning would have saved them considerable money and hassle. Let’s explore the critical factors you should consider before making this important purchase for your stable.

Why Are Horse Stall Mats Important For Joint Protection?

Horse stall mats are crucial for joint protection because they absorb impact forces that would otherwise travel directly through your horse’s hooves and legs. The cushioning effect reduces concussion on joints, ligaments, and tendons, particularly beneficial for older horses or those recovering from injuries. This protection helps prevent long-term joint deterioration and keeps horses comfortable.

When horses stand on hard surfaces like concrete or packed dirt for extended periods, their joints absorb significant stress. This constant pressure contributes to inflammation, soreness, and potentially career-ending conditions like navicular disease or arthritis. I’ve seen this repeatedly in my years at the rubber flooring factory – proper cushioning makes a tremendous difference in horse comfort and soundness.

Impact on Long-Term Horse Health

High-quality rubber mats provide the perfect balance between firmness and shock absorption. Unlike overly soft bedding that might cause instability, properly engineered rubber delivers consistent support while buffering impact. Our manufacturing process focuses on creating the optimal density – firm enough to provide secure footing yet yielding enough to protect delicate joint structures.

The thickness of the mat directly correlates with its protective qualities. While 3/4-inch mats represent the industry standard, I recommend 1-inch or thicker mats for competition horses, breeding stock, or animals with existing joint issues. The additional cushioning may seem like a small difference, but the cumulative effect over thousands of hours of standing can significantly extend your horse’s active years.

Many stable owners I’ve consulted initially underestimate the importance of proper stall flooring. After installing quality mats, they frequently report noticeable improvements in their horses’ movement, comfort, and overall happiness, especially in animals previously showing signs of joint discomfort.

How Do Horse Stall Mats Prevent Slipping And Injuries?

Horse stall mats prevent slipping by providing textured surfaces that offer secure footing even when wet. This traction is critical during a horse’s sudden movements, helping maintain balance and preventing dangerous falls. The anti-slip properties significantly reduce the risk of muscle strains, torn ligaments, and more serious injuries that could result from slipping on slick surfaces.

In our factory testing facility, we’ve developed specific texturing processes to maximize grip without creating surfaces that trap debris or become difficult to clean. Through countless iterations, we’ve found that a medium-depth texture pattern offers the optimal balance between traction and practicality.

Critical Traction Features

The most effective stall mats feature:

- Uniform surface patterns that drain properly while maintaining grip

- Textured bumps or grooves that increase surface area contact with hooves

- Slip-resistant properties that work in both dry and wet conditions

- Edges designed to fit tightly together to prevent tripping hazards

Horses are surprisingly prone to panic when they feel unstable footing. A startled horse on a slippery surface can quickly injure itself or handlers. I’ve received feedback from countless stable owners who’ve noted dramatic reductions in nervous behavior after installing properly textured mats, particularly with young or high-strung animals.

I recently visited a rehabilitation facility that switched to our premium textured mats. The head trainer told me they’ve been able to bring horses back into work nearly two weeks earlier on average, as the secure footing allows for confident movement during the critical healing phase. This aspect of stall mats often goes overlooked until you see the difference it makes.

How Effective Are Stall Mats At Absorbing Impact And Noise?

Stall mats excel at absorbing both impact and noise through their dense rubber composition. Quality rubber mats can reduce impact forces by up to 30% compared to concrete or dirt floors, protecting hooves from concussive damage. They simultaneously minimize the noise from hoof strikes, pawing, and movement, creating a calmer environment that benefits both horses and handlers.

The noise reduction qualities of rubber stall mats shouldn’t be underestimated. I’ve visited stables before and after installing our mats, and the difference in ambient noise is remarkable. The constant sounds of hooves on hard surfaces create an unconscious stress level that affects both animals and humans.

Sound and Impact Absorption Properties

From my experience overseeing rubber manufacturing, I can tell you that several factors influence a mat’s absorption capabilities:

- Density: Higher density rubber provides better impact absorption

- Thickness: Thicker mats dampen more sound and impact

- Composition: The precise rubber formula affects elasticity and resilience

- Manufacturing process: How the rubber is compressed and cured

In practical terms, this translates to quieter stables, less hoof wear, and reduced stress on your horse’s musculoskeletal system. For facilities with multiple horses, the cumulative noise reduction creates a noticeably more peaceful environment, which veterinarians tell us can improve overall equine health and behavior.

I recall one boarding facility owner who called me six months after installation to share that her boarders had reported their horses seemed calmer and more relaxed since the new flooring was installed. The reduction in ambient noise had created a more natural environment that reduced stress behaviors throughout the barn.

What Kind Of Drainage Or Moisture Resistance Do Stall Mats Provide?

Quality stall mats offer excellent moisture resistance with non-porous surfaces that prevent liquid absorption. When properly installed with tight seams, they create a protective barrier that keeps urine and water from penetrating to subfloors. This resistance significantly improves hygiene, reduces ammonia odors, and protects both the subfloor and mat structure from moisture damage.

In our factory, we’ve developed specialized rubber compounds specifically engineered to resist the corrosive effects of horse urine. This is crucial because regular exposure to ammonia can break down inferior materials, creating cracks and deterioration that compromise both cleanliness and safety.

Effective Drainage Systems

The most effective moisture management comes from combining quality mats with proper stall design:

- Stall floor sloping (1-2% grade toward drains)

- Properly sealed mat seams

- Non-absorbent, chemical-resistant rubber compounds

- Textured surfaces that encourage liquid runoff

I’ve seen firsthand how proper drainage extends mat lifespan. Stables using our recommended installation methods report mat lifespans 3-5 years longer than those with improper drainage. The initial effort to prepare the subfloor correctly pays substantial dividends over time.

I recently consulted with a stable that had been replacing their economy mats every 2-3 years due to deterioration. After switching to our premium moisture-resistant mats and implementing proper drainage, they’ve now gone over 7 years without replacement needs. The upfront investment delivered significant long-term savings.

How To Compare Stall Mat Density And Durability?

When comparing stall mat density and durability, examine the mat’s weight-to-size ratio, as denser mats are typically heavier and more durable. Quality mats should feel firm but slightly yielding when pressed, with minimal compression under heavy pressure. Look for tensile strength specifications of at least 800 PSI and shore hardness readings between 65-75A for optimal performance and longevity.

In our factory quality control process, we test every production batch for density consistency. This might seem excessive, but uniform density ensures even wear and consistent performance throughout the mat’s lifespan. Inconsistent density often indicates poor manufacturing practices that will lead to premature failure.

Key Durability Indicators

When evaluating stall mat options, consider these technical aspects:

- Weight: Heavier mats generally indicate higher rubber content and durability

- Edge quality: Clean, precise cuts suggest careful manufacturing

- Rebound: Quality rubber should return to shape quickly after compression

- Warranty: Longer warranties typically reflect manufacturer confidence

I’ve found that the most reliable indicator of durability is density combined with proper rubber formulation. Some manufacturers attempt to increase weight using inexpensive fillers that actually reduce performance. Our premium mats use specific rubber compounds developed through decades of performance testing in actual stable environments.

One large breeding operation I work with tracks their equipment expenses meticulously. Their data showed that our high-density mats cost approximately 40% more upfront but lasted 2.3 times longer than the economy options they had previously used, resulting in significant cost savings over a 10-year period.

Can Cheap Stall Mats Last Long Enough?

Cheap stall mats rarely last long enough to justify their lower initial cost. Low-quality mats typically deteriorate within 2-3 years, developing cracks, separating at edges, and losing shock absorption properties. While premium mats might cost 30-50% more initially, their 7-10 year lifespan delivers substantially better value while providing consistent protection for your horse throughout their service life.

As a production manager, I’ve analyzed the composition of many competitor products. Economy mats often use higher percentages of fillers and lower-grade rubber, resulting in faster degradation when exposed to the harsh stable environment. The manufacturing shortcuts become evident within months of installation.

The True Cost of Economy Options

When calculating the real cost of cheap mats, consider:

- Replacement frequency (typically 2-3 times more often)

- Installation labor for each replacement

- Disposal costs of worn mats

- Inconsistent protection for your horse

- Potential for subfloor damage from seeping moisture

I’ve worked with dozens of stables that initially chose budget options only to switch to premium mats after experiencing rapid deterioration. The lesson they learned: in stall flooring, the cheapest option almost always becomes the most expensive over time.

A commercial stable I supply recently shared that they had previously replaced their entire barn with economy mats three times in seven years before switching to our premium product. They haven’t needed replacements in the five years since, and the mats still show minimal wear. Their experience demonstrates why calculating long-term cost is essential.

What’s The Typical Lifespan Of Horse Stall Mats?

High-quality horse stall mats typically last 7-10 years with proper installation and maintenance. Premium mats maintain their protective properties throughout their lifespan, whereas economy options may physically last 3-5 years but lose their crucial shock-absorbing qualities much sooner. Factors like horse weight, activity level, maintenance practices, and initial installation quality significantly impact longevity.

From my production experience, I can tell you that manufacturing quality directly correlates with lifespan. The vulcanization process we use for premium mats creates stronger molecular bonds in the rubber, resulting in greater resistance to the constant compression, moisture, and ammonia exposure found in horse stalls.

Maximizing Mat Longevity

To achieve maximum lifespan from your investment:

- Install on properly prepared, level surfaces

- Seal seams to prevent moisture penetration

- Clean regularly with appropriate cleansers

- Address any shifting or separation immediately

- Use adequate bedding to distribute urine and reduce direct exposure

I’ve noticed that stalls with regularly rotated occupancy tend to have more uniform wear patterns, extending overall lifespan. Strategic mat placement can also help – using your most durable mats in high-traffic areas like stall entrances and repositioning mats periodically to distribute wear.

I remember visiting a stable that had installed our premium mats when they opened. Twelve years later, the original mats were still in service in lower-traffic areas, while only the main walkways and stall entrances had needed replacement. Their meticulous maintenance routine had nearly doubled the expected lifespan.

Where Can I Buy Reliable Horse Stall Mats?

Reliable horse stall mats are available through specialized equine suppliers, agricultural stores, and direct from manufacturers like our company. When selecting a supplier, look for those with extensive equine experience, detailed product specifications, clear warranty terms, and positive reviews from other horse owners. Avoid general retailers selling multi-purpose mats not specifically designed for the unique demands of horse stalls.

As someone who has supplied mats to the equine industry for years, I strongly recommend purchasing from businesses that understand horses and stables. Their product selection typically reflects the specific needs of equine environments rather than general-purpose rubber flooring.

Evaluating Reliable Suppliers

The most trustworthy suppliers will provide:

- Detailed density and hardness specifications

- Clear warranty information

- Installation guidelines specific to horse stalls

- Sample materials upon request

- References from other equine facilities

I’ve seen that direct relationships with manufacturers often provide the best combination of quality assurance and value. Many quality manufacturers (like us) sell both through distributors and directly to large operations, offering technical support that general retailers cannot match.

One of our client stables initially ordered from a general agricultural supply store before contacting us directly. The difference in technical assistance made a significant impact – we were able to recommend specific mat configurations based on their facility layout and horse population, resulting in optimized protection and durability.

Can Horse Stall Mats Be Used In Trailer Floors Or Grooming Areas?

Horse stall mats work excellently in trailer floors and grooming areas when selected appropriately. For trailers, thinner (1/2 inch) high-density mats reduce weight while providing necessary traction during transport. In grooming areas, thicker mats (3/4-1 inch) with enhanced slip resistance are ideal to support horses standing for extended periods. Both applications require secure installation to prevent shifting and tripping hazards.

In our product development, we’ve created specialized formulations for different equine applications. Trailer mats face unique challenges – they must be simultaneously lightweight, extremely durable, and capable of withstanding temperature fluctuations and vibration not present in stables.

Application-Specific Considerations

When adapting stall mats for other uses:

- Trailer floors: Focus on secure fastening methods to prevent shifting during transport

- Grooming areas: Prioritize enhanced drainage for frequent washing

- Wash stalls: Select chemical-resistant formulations that withstand cleaning agents

- Tack rooms: Consider lighter-weight options with enhanced comfort for human use

I’ve advised many clients on cross-application uses. The most successful installations occur when the mat properties are matched to the specific environmental challenges of each area. For instance, grooming areas benefit from more aggressive texturing than stalls due to the presence of soaps and grooming products.

A professional trainer I work with created a comprehensive rubber flooring system throughout her facility, using different mat specifications for each area. The integration created a consistent feel for the horses while optimizing performance characteristics for each specific use case – an approach I now recommend to all commercial facilities.

What Other Areas In A Stable Can Benefit From Stall Mats?

Beyond stalls, rubber mats benefit numerous stable areas, including wash bays, aisle ways, breeding areas, and veterinary examination spaces. Mats in feed rooms protect dropped grain from moisture, while tack room installations reduce fatigue for humans and protect dropped equipment. Strategic mat placement in high-traffic areas prevents dirt floor erosion and dust, creating a cleaner, safer facility with consistent footing throughout.

From my experience with comprehensive stable installations, I’ve found that extending rubber flooring beyond stalls creates both practical and safety advantages. Consistent footing throughout a facility reduces horse anxiety during transitions between spaces – a benefit many owners don’t anticipate until they experience it.

Strategic Placement for Maximum Benefit

Consider these specialized applications:

- Mounting areas: Extra-thick mats reduce impact when riders dismount

- Wash bays: Specialized drainage patterns enhance water removal

- Breeding areas: Maximum traction prevents injuries during natural breeding

- Foaling stalls: Softer formulations provide cushioning for newborns

I’ve consulted on several facility renovations where strategic mat placement transformed problem areas. For example, one training barn struggled with persistent mud at barn entrances until installing our heavy-duty transition mats, which dramatically improved cleanliness throughout the facility.

A boarding facility I work with recently created a fully matted pathway system connecting their barn, arena, and turnout areas. They reported a notable decrease in hoof issues and respiratory problems once horses were no longer transitioning between different surfaces throughout the day. The consistent footing created a measurably healthier environment.

Can Horse Stall Mats Be Used For Cows, Dogs, Or Other Animals?

Horse stall mats are highly adaptable for other animals with appropriate thickness adjustments. For cattle, the same thickness works well, providing joint protection in dairy parlors and calving areas. Dog kennels benefit from thinner (3/8-1/2 inch) mats that offer insulation while resisting chewing. Zoo facilities often use our thickest options (1-1/2 inch) for large exotic species, as the mats reduce joint stress while withstanding varied animal behaviors.

In our manufacturing facility, we’ve developed specific formulations for different animal applications based on extensive feedback from veterinarians and animal care professionals. While the base technology is similar, subtle adjustments to density, texture, and thickness optimize performance for each species.

Species-Specific Adaptations

Key considerations when adapting horse stall mats include:

- Cattle: Enhanced acid resistance for dairy environments

- Dogs: Smoother textures that are easier to fully sanitize

- Exotic animals: Specialized scent-neutral formulations for sensitive species

- Small ruminants: Modified texture patterns to accommodate smaller hooves

I’ve worked closely with several large dairy operations that transitioned from concrete to rubber flooring. Their data showed significant improvements in hoof health, milk production, and breeding success – benefits directly attributable to the reduction in joint stress and improved comfort.

One of our most interesting projects involved developing custom rubber flooring for a zoological institution’s elephant habitat. The specialized requirements led to innovations we’ve since incorporated into our premium horse stall products – a perfect example of how cross-species applications advance the entire product category.

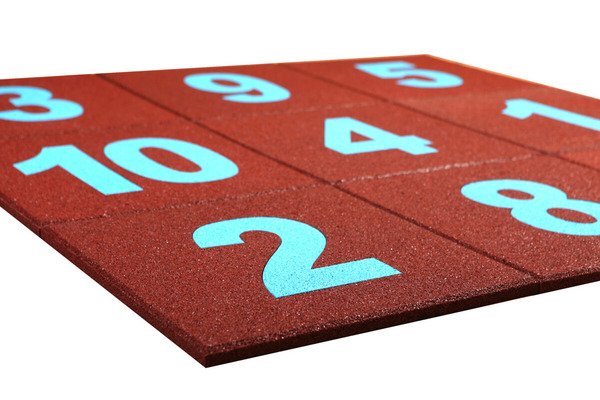

How Can Custom Logos Or Patterns Be Added To Stall Mats?

Custom logos and patterns can be added to stall mats through inlaying, surface printing, or molded integration techniques. Inlaying involves cutting and inserting contrasting rubber pieces for permanent, wear-resistant designs. Surface printing applies specialized rubber-compatible inks that bond molecularly with the mat surface. For larger orders, we can create custom molds that integrate designs directly into the mat structure during manufacturing.

As a production manager, I’ve overseen hundreds of custom projects, from simple barn name inlays to complex decorative patterns for high-end equestrian facilities. These personalized elements add both branding opportunities and practical benefits like visual guidance for horse positioning.

Customization Methods and Durability

The most effective customization approaches include:

- Inlaid rubber: Most durable, with designs lasting the life of the mat

- Vulcanized printing: High durability with more color options

- Molded integration: Highest quality but requires larger minimum orders

- Surface application: Most affordable but less durable

I’ve found that practical customization often delivers unexpected benefits. For example, one training facility added position markers to their stall mats to ensure consistent horse placement during grooming and veterinary procedures. This simple addition improved efficiency and safety for both horses and handlers.

A memorable project involved creating custom mats for an international competition venue. We integrated directional guides and staging position markers directly into the flooring throughout the facility. Competitors reported that these subtle visual cues significantly reduced pre-competition stress for both horses and riders by clarifying traffic patterns.

Wnioski

Selecting the right horse stall mats requires understanding material quality, thickness requirements, installation methods, and long-term maintenance needs. Quality mats protect your horse’s joints, prevent injuries, and create a healthier stable environment while delivering superior long-term value despite higher initial costs.