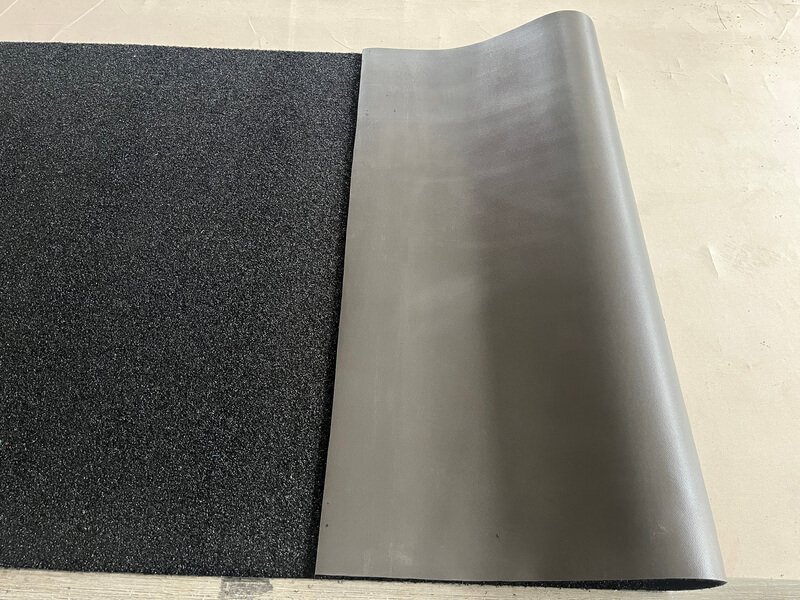

As a production manager specializing in 5mm PU backing padding turf, I can tell you the key is understanding cushioning performance and joint protection. Our 5mm polyurethane backing provides superior comfort and durability for indoor high-intensity training, with exceptional bonding strength that prevents delamination.

After managing turf production for over a decade, I’ve witnessed the evolution from basic artificial grass to sophisticated padding systems. The breakthrough came with 5mm PU backing technology that revolutionized indoor fitness applications. Unlike drainage-based outdoor turfs, our indoor padding turf focuses purely on cushioning performance and joint protection for members engaged in high-intensity training.

The difference between standard turf and proper padding turf lies in understanding biomechanics and impact forces. Let me share the technical insights that separate quality products from cheap alternatives.

What Makes 5mm PU Backing Superior for Indoor Training?

The 5mm polyurethane backing creates optimal energy absorption while maintaining surface stability. Unlike rubber or foam alternatives, PU backing provides consistent cushioning across temperature ranges while forming an unbreakable bond with grass fibers that prevents delamination under stress.

In our manufacturing process, we’ve perfected the PU formulation to achieve the ideal balance between cushioning and stability. The 5mm thickness provides approximately 35-40% impact absorption, which our testing shows is the sweet spot for joint protection without compromising explosive movement performance.

Technical Advantages of Our PU Backing System:

- Molecular Bonding: Chemical adhesion prevents fiber separation

- Temperature Stability: Consistent performance from 10-35°C

- Impact Distribution: Even force dispersion across the surface

- Memory Recovery: Returns to original thickness after compression

- Weight Distribution: 6.5kg/sqm provides stability without bulk

The bonding strength between our PU backing and grass fibers exceeds 25N/cm in peel tests. This means the composite structure performs as a single unit rather than separate layers that can delaminate. I’ve seen competitors’ products where the grass separates from backing after months of use, creating dangerous surface irregularities.

Our 6.5kg per square meter weight provides the perfect balance. Lighter products lack stability and move during dynamic exercises, while heavier alternatives become difficult to install and may stress subfloor structures.

The indoor-specific design eliminates drainage holes that would compromise cushioning integrity, focusing entirely on comfort and performance optimization.

How Does Superior Cushioning Protect Joints During High-Intensity Training?

The 5mm PU backing absorbs impact forces that would otherwise transfer directly to joints, reducing stress on knees, ankles, and spine by up to 40%. The cushioning effect is most pronounced during explosive movements, directional changes, and ground-based exercises where traditional hard surfaces cause cumulative damage.

During high-intensity training, members generate impact forces 3-5 times their body weight. Without proper cushioning, these forces travel directly through the kinetic chain, causing micro-trauma that accumulates over time. Our PU backing system interrupts this force transmission while maintaining the surface stability needed for performance.

Biomechanical Benefits in Training Applications:

- Plyometric Exercises: Reduced landing impact while maintaining energy return

- Agility Training: Joint protection during rapid direction changes

- Floor Exercises: Comfortable surface contact without pressure points

- Equipment Workouts: Stable platform with shock absorption

- Recovery Sessions: Gentle surface for rehabilitation movements

The foot-feel experience is dramatically different from hard surfaces. Members immediately notice the comfort improvement, which translates to longer training sessions and reduced fatigue. The psychological benefit is significant – when people feel comfortable, they train with more confidence and intensity.

Our cushioning remains consistent across the entire surface. Unlike foam systems that develop soft spots or hard surfaces that create pressure points, the PU backing maintains uniform performance characteristics throughout its lifespan.

The comfort factor directly impacts member retention and satisfaction scores, making it a valuable investment for facility operators.

Why Does Bonding Strength Matter More Than You Think?

Superior bonding prevents the catastrophic delamination failures that plague inferior products. Our PU backing creates molecular-level adhesion with grass fibers, eliminating the separation issues that create safety hazards and require premature replacement.

In production, we control every aspect of the bonding process. Temperature, pressure, and cure time are precisely managed to achieve optimal adhesion. The PU material flows into the fiber structure, creating mechanical interlocking combined with chemical bonding.

Manufacturing Quality Control Points:

- Fiber Preparation: Surface treatment for optimal adhesion

- PU Application: Controlled thickness and coverage

- Curing Process: Temperature and time optimization

- Bond Testing: Peel strength verification for every batch

- Quality Inspection: Visual and mechanical testing protocols

Delamination typically occurs at stress points where furniture legs, equipment, or concentrated loading creates peel forces. Our bonding strength testing simulates these conditions to ensure long-term integrity. Products that fail these tests won’t survive real-world applications.

The composite performance means the turf behaves as a single material rather than grass sitting on backing. This unity is crucial for consistent performance and prevents the edge lifting that creates trip hazards in high-traffic areas.

Inferior bonding leads to progressive failure that starts small but accelerates, ultimately requiring complete replacement rather than simple repairs.

How Do We Achieve Custom Colors and Patterns Successfully?

Our advanced tufting machines can weave unlimited color combinations and custom patterns directly into the grass structure. After weaving the complete turf with integrated patterns, we bond it with PU backing to create a permanent composite that maintains pattern integrity throughout its lifespan.

The magic happens in our computerized tufting process where we can program specific color placements with millimeter precision. Unlike surface printing or post-production treatments, our patterns are woven into the turf structure during manufacturing. This means the design elements are as durable as the grass fibers themselves.

Our Customization Manufacturing Process:

- Digital Design: CAD pattern programming for tufting machines

- Yarn Selection: Solution-dyed fibers for fade resistance

- Precision Tufting: Computer-controlled fiber placement

- Pattern Verification: Quality checks during production

- PU Bonding: Composite formation preserving pattern integrity

After the tufting process creates the patterned grass, we apply the 5mm PU backing through our specialized bonding process. The PU material secures every fiber in its exact position, preventing pattern distortion or color bleeding over time. This manufacturing sequence ensures that logos, geometric patterns, or zone markings remain crisp and vibrant.

Color matching capabilities extend to any Pantone specification. Our solution-dyed fiber system allows us to match corporate colors precisely, supporting brand consistency across training spaces. We can create gradient effects, multi-zone color schemes, or integrate safety markings that become permanent parts of the surface.

The investment in custom patterns pays dividends through enhanced brand recognition and improved space functionality that standard products cannot deliver.

What Should You Look for When Selecting a Reliable Padding Turf Manufacturer?

Trustworthy manufacturers demonstrate quality through CE and SGS certifications, comprehensive testing facilities, and transparent production processes. Look for manufacturers with documented quality systems, certified testing capabilities, and willingness to provide detailed performance data.

Having worked in manufacturing for years, I’ve seen how quality standards separate professional producers from fly-by-night operations. The manufacturers worth considering invest in proper certifications, maintain rigorous testing protocols, and operate with complete transparency about their processes and capabilities.

Essential Quality Certifications and Standards:

- CE Certification: European Conformity marking for safety standards

- SGS Testing: Independent third-party quality verification

- ISO 9001: Quality management system certification

- Production Documentation: Batch tracking and process control

- Performance Testing: In-house laboratories with certified equipment

CE certification ensures our products meet European safety and performance standards for sports surfaces. This isn’t just paperwork – it requires regular audits and testing to maintain certification status. SGS testing provides independent verification of our performance claims through internationally recognized testing protocols.

Our in-house testing facility performs daily quality checks on bonding strength, impact absorption, fiber pull resistance, and dimensional stability. We maintain complete batch records allowing us to trace every square meter back to specific raw materials and production conditions.

Warning Signs of Unreliable Manufacturers:

- No recognized certifications or vague quality claims

- Reluctance to provide test data or production samples

- Pricing significantly below market without technical justification

- Limited warranty terms or unclear warranty conditions

- Inability to demonstrate manufacturing capabilities

Quality manufacturers welcome facility visits and take pride in showing their operations. They understand that transparency builds confidence and long-term relationships. If a manufacturer won’t provide detailed specifications, test results, or facility access, consider that a major red flag.

The relationship extends far beyond the initial sale, making manufacturer reliability and support capabilities crucial for your long-term success.

How Do You Evaluate Total Cost of Ownership?

Total cost includes initial investment, installation requirements, maintenance needs, and replacement timeline. Our 5mm PU backing typically provides 8-12 year service life with proper care, making cost per year significantly lower than cheaper alternatives that require frequent replacement.

Cost evaluation must consider the complete ownership cycle. Initial price differences often disappear when you factor in performance longevity, maintenance requirements, and replacement frequency. Our premium PU backing system costs more initially but delivers superior value over time.

Cost Analysis Framework:

- Material Cost: Price per square meter including shipping

- Wymagania instalacyjne: Professional installation and preparation needs

- Maintenance Costs: Cleaning supplies and labor requirements

- Performance Longevity: Expected service life under normal use

- Replacement Planning: Future replacement and disposal costs

Our 6.5kg weight requires proper subfloor support but eliminates the shifting and movement issues that plague lighter products. The installation investment pays dividends through consistent performance and reduced maintenance needs.

Maintenance costs are minimal due to the PU backing’s resistance to moisture absorption and bacterial growth. The smooth backing surface doesn’t trap contaminants like foam alternatives, reducing cleaning time and chemical requirements.

Quality products like ours deliver 40-60% lower total cost of ownership compared to budget alternatives when analyzed over realistic timeframes.

Wnioski

Selecting quality 5mm PU backing padding turf requires understanding cushioning technology, bonding strength, and manufacturer reliability to ensure optimal joint protection and long-term value.

Ready to experience the superior comfort and performance of our 5mm PU backing padding turf? As the production manager, I personally oversee every batch to ensure consistent quality. Contact us today for custom color samples, detailed specifications, and a factory tour. Let me show you exactly how our manufacturing process creates the most comfortable and durable indoor training surface available. Your members’ joints will thank you, and your bottom line will benefit from the superior longevity and performance our padding turf delivers.