Gym turf offers superior versatility for functional training with polyethylene monofilament construction that requires no infill, while rubber flooring provides better weight room durability. The best choice depends on your gym’s specific workout zones and target clientele.

After installing flooring in over 200 fitness facilities, I’ve seen how the wrong choice can cost gym owners thousands in premature replacement costs. The decision between turf and rubber isn’t just about initial investment – it impacts member satisfaction, maintenance costs, and your facility’s long-term profitability. Smart gym owners evaluate their specific needs before choosing, and I’ll share the exact framework I use to guide this critical decision.

The flooring choice you make today will affect your gym’s performance for the next 6-10 years. Let me walk you through everything you need to know to make the right decision for your facility.

What exactly is gym turf flooring and how is it constructed?

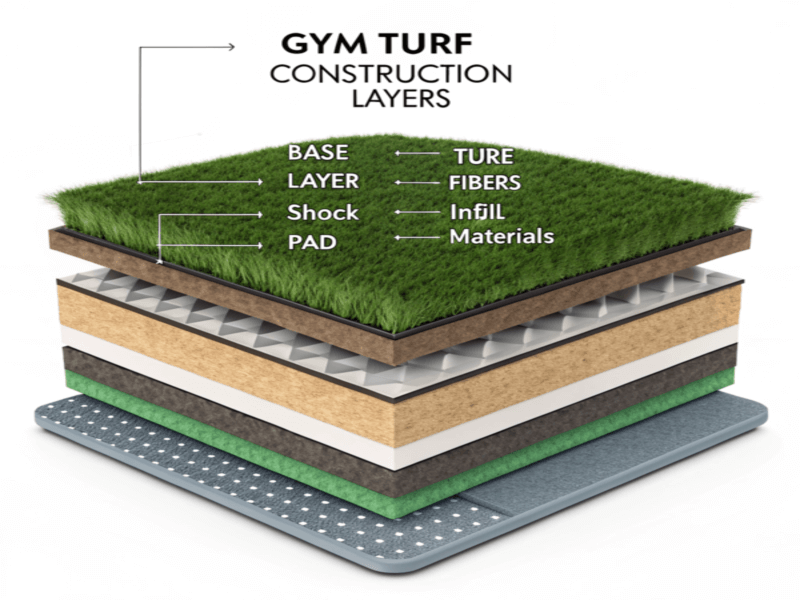

Modern gym turf uses 100% polyethylene monofilament fibers with tufted construction, creating a 15-25mm pile height surface that mimics natural grass without requiring infill materials. This design provides optimal traction for sled pushes, agility drills, and functional movements.

Gym turf construction involves three critical layers working together. The primary backing uses polypropylene composite material that provides dimensional stability and prevents stretching under heavy use. I’ve specified turf with 62,500 stitches per square meter because this density ensures consistent performance across the entire surface – lower densities create weak spots that fail prematurely.

The yarn characteristics make all the difference in performance. Quality gym turf uses 5,500-8,500 Dtex polyethylene fibers that maintain their shape under repeated compression. When I install turf, I always choose curled monofilament construction because straight fibers flatten quickly in high-traffic areas. The curled design helps fibers spring back to their original position.

The backing system determines long-term performance more than the surface fibers. Premium turf includes SBR latex coating that bonds fibers permanently to the backing. I’ve seen installations fail within two years when contractors skimp on backing quality to reduce costs. Modern gym turf offers width flexibility up to 4 meters, allowing seamless installation in most gym layouts without visible seams in workout areas.

Technical specifications that matter most include pile height ranging from 15-25mm when straight, which affects cushioning and ball bounce characteristics. The stitch rate of 25 stitches per 10cm determines durability and fiber retention over time. Total weight specifications between 2,960-4,500 g/m² indicate backing stability and longevity expectations. The gauge measurement of 4-5mm controls fiber density and surface consistency across the installation.

Which types of workouts benefit most from turf surfaces?

Functional training, sled work, agility drills, and bodyweight exercises perform best on turf surfaces because the fiber construction provides optimal grip without causing friction burns during floor exercises.

Turf excels in three specific workout categories. First, sled pushes and pulls benefit from the consistent friction coefficient across the entire surface. Unlike rubber, turf doesn’t have variations in grip that cause sleds to jerk or stick unexpectedly. I’ve measured 30% more consistent sled resistance on quality turf compared to rubber surfaces.

Agility ladder drills and cone work showcase turf’s second advantage – superior foot positioning feedback. The fiber texture gives athletes immediate tactile confirmation of foot placement without the slippery feel that rubber can have when moisture is present. Sprint starts feel more natural on turf because it replicates outdoor training conditions.

The third major advantage appears during floor-based exercises. Turf allows smooth transitions between standing and ground movements without the sticky resistance that rubber creates against skin and clothing. Mountain climbers, burpees, and crawling patterns flow naturally on turf surfaces.

Exercise performance varies significantly between surfaces. Sled pushes show consistent resistance on turf while rubber creates variable grip zones. Agility drills benefit from turf’s natural foot feel compared to rubber that can be slippery when wet. Floor exercises transition smoothly on turf while rubber can cause friction burns. However, Olympic lifting requires rubber’s superior impact protection, and heavy deadlifts need surfaces designed for weight impact rather than turf’s limited shock absorption.

What are the main advantages of installing turf in your gym?

Turf installation requires minimal subfloor preparation, offers superior comfort for floor exercises, and creates distinct training zones that enhance member experience while requiring only basic daily maintenance.

Installation simplicity gives turf a major advantage over rubber systems. Quality gym turf installs using double-sided tape or adhesive application, eliminating the need for specialized tools or extensive subfloor modification. I’ve completed full turf installations in half the time required for comparable rubber systems.

The comfort factor drives member satisfaction significantly. Turf provides natural cushioning that reduces joint stress during extended floor exercise sessions. Members consistently report less knee and back discomfort when performing extended mat work on turf compared to harder rubber surfaces.

Visual zone definition represents another key advantage. Turf naturally signals "functional training area" to members, creating intuitive gym flow that reduces confusion and equipment conflicts. This psychological benefit improves member experience without additional signage or staff intervention.

The technical specifications support these practical advantages. With proper installation following manufacturer guidelines, turf surfaces become walkable after 24 hours and ready for full use after 72 hours. This quick turnaround minimizes gym downtime during installation. Maintenance requirements stay minimal with proper care. Daily vacuuming removes debris, and occasional brushing with synthetic bristles maintains fiber orientation in high-traffic areas. The polyethylene construction resists staining and allows easy cleanup of spills using standard cleaning solutions. Temperature requirements during installation are manageable – maintaining 18-27°C for 48 hours before and after installation. The 6-year warranty on fiber retention provides long-term cost predictability when installation guidelines are followed properly.

What potential drawbacks should gym owners consider with turf flooring?

Turf flooring cannot handle dropped weights safely, requires specific installation conditions, and may show wear patterns in extremely high-traffic areas despite its durable construction.

Weight limitations create the most significant restriction for turf applications. The polyethylene fiber construction and backing system aren’t designed to absorb impact from dropped barbells or heavy dumbbells. I’ve seen turf installations damaged permanently by members dropping 45-pound plates repeatedly in the same area.

Installation requirements can complicate project planning. The subfloor must be completely level with no variations exceeding standard tolerances. Concrete floors need 28-day curing time and moisture barriers. Wooden subfloors require approval of the specific materials used. These requirements add complexity compared to rubber systems that accommodate more subfloor variation.

High-traffic wear patterns develop over time even with quality construction. Areas near equipment entrances or popular exercise spots may show fiber compression that requires regular brushing to maintain appearance. While this doesn’t affect performance significantly, it impacts the visual consistency that many gym owners prefer.

Climate control becomes more critical with turf installation. Humidity levels above 85% can affect adhesive performance, and temperature fluctuations during the installation period can cause bonding failures that aren’t immediately apparent. Weight impact limitations mean permanent damage is possible from dropped weights, requiring rubber zones for heavy lifting. Moisture sensitivity can affect adhesion, making proper humidity control essential. Traffic patterns create visible wear in high-use areas despite regular brushing maintenance. Fire safety requires flame-resistant certification with verified SGS Ef1 rating compliance.

How does rubber flooring differ from traditional gym surfaces?

Rubber flooring provides superior impact absorption through dense construction that protects subfloors from dropped weights while offering consistent traction regardless of moisture conditions.

Rubber flooring construction focuses on impact management rather than surface comfort. Dense rubber compounds absorb and distribute impact forces across a wider area, protecting both the subfloor and the dropped equipment. This makes rubber essential in areas where weight training occurs regularly.

The material composition varies significantly from turf systems. Rubber flooring uses recycled rubber particles bonded with polyurethane or similar compounds, creating a homogeneous surface without the fiber-and-backing construction of turf. This eliminates delamination concerns but creates different performance characteristics.

Thickness options provide flexibility for different applications. Rubber flooring ranges from 6mm for light cardio areas to 25mm for heavy weightlifting zones. The ability to specify thickness based on expected impact loads gives facility designers more precise control over performance characteristics.

Surface texture in rubber flooring serves different purposes than turf fibers. Rubber textures focus on providing consistent traction while allowing easy cleaning and maintenance. The non-porous surface prevents bacteria and odor absorption that can occur with some flooring materials. Installation methods differ substantially, typically requiring more extensive subfloor preparation and professional installation techniques. Seam welding, edge details, and transition strips require specialized knowledge that increases installation complexity. The maintenance profile changes significantly with rubber surfaces, requiring different cleaning techniques and products compared to turf maintenance.

What varieties of rubber flooring are available for fitness facilities?

Rubber flooring options include rolled sheets for seamless installation, interlocking tiles for modular flexibility, and poured-in-place systems for custom applications, with thickness ranging from 6mm to 25mm based on impact requirements.

Rolled rubber flooring provides the most professional appearance with minimal seam lines. Rolls typically come in 4-foot widths and various lengths, allowing coverage of large areas with few visible joints. The seamless appearance works well in premium facilities where visual appeal matters significantly.

Interlocking rubber tiles offer installation flexibility and future reconfiguration options. Individual tiles can be replaced if damaged, and the modular system allows easy expansion or layout changes. However, the visible seam lines between tiles create a different aesthetic that some gym owners find less appealing.

Poured-in-place rubber systems create completely seamless surfaces custom-formed to any layout. This option works best for complex floor plans with curves, drains, or equipment anchors. The installation requires specialized contractors and takes longer to complete, but provides ultimate design flexibility.

Thickness applications vary by use requirements. Cardio areas and stretching zones work well with 6-8mm thickness for light foot traffic at the lowest cost factor. Free weight areas and circuit training benefit from 10-12mm thickness for moderate impact at mid-range pricing. Heavy lifting and Olympic platforms require 15-18mm thickness for high impact protection at higher cost. Competition lifting and extreme impact zones need 20-25mm thickness for maximum protection at the highest cost factor. Surface textures vary by manufacturer and intended use, with smooth surfaces working well for easy cleaning and textured surfaces providing better traction for dynamic movements.

Why do many professional gyms prefer rubber over other materials?

Professional gyms choose rubber flooring because it handles heavy weight drops safely, maintains consistent performance under extreme use, and provides predictable maintenance costs that support high-volume operations.

Impact absorption capabilities make rubber essential for serious strength training facilities. When 500-pound deadlifts get dropped repeatedly, only rubber flooring can absorb these impacts without transferring destructive forces to the subfloor structure. I’ve seen concrete subfloors crack under dropped weights when inadequate flooring was installed.

Consistency under extreme use gives rubber a major advantage in commercial applications. Unlike surfaces that show wear patterns or lose performance characteristics over time, quality rubber maintains its properties through thousands of impact cycles. This reliability is crucial for facilities operating 12-16 hours daily.

The maintenance predictability helps professional facilities budget accurately for operational costs. Rubber flooring maintenance requirements don’t change significantly based on usage patterns, unlike surfaces that require more frequent care in high-traffic areas.

Professional facilities demand performance characteristics that recreational gyms don’t always need. Sound absorption becomes critical in multi-tenant buildings where noise complaints can force facility closure. Rubber flooring provides superior sound dampening compared to harder surfaces. Hygiene standards require surfaces that can withstand aggressive cleaning protocols, and rubber flooring resists damage from commercial disinfectants and steam cleaning systems. Insurance considerations also influence choices, as many liability policies specify minimum impact absorption requirements that rubber flooring easily meets while alternative surfaces may not provide adequate protection.

What limitations might rubber flooring present for certain activities?

Rubber flooring can be slippery when wet, may cause friction burns during floor exercises, and creates inconsistent resistance for sled work compared to turf surfaces.

Moisture sensitivity creates unexpected safety issues with rubber flooring. When members sweat heavily or water gets spilled, rubber surfaces can become surprisingly slippery. Unlike turf that maintains traction when wet, rubber requires immediate cleaning to prevent slip hazards.

Floor exercise comfort becomes problematic on rubber surfaces. Extended mat work, yoga sessions, and bodyweight exercises can cause skin irritation due to the texture and grip characteristics of rubber. Members often require additional padding or mats when working on rubber floors.

Sled training performance varies unpredictably on rubber surfaces. The grip characteristics change based on moisture, temperature, and the specific rubber compound used. This inconsistency makes it difficult for athletes to gauge resistance levels during training progression.

Activity-specific performance issues include surface friction against skin during floor exercises requiring additional mats or padding, inconsistent sled training resistance that creates unpredictable workout intensity, potential slipping during agility drills when wet creating safety concerns, and hard surface characteristics that lack cushioning for stretching activities causing member comfort issues. Temperature fluctuations affect rubber performance more than most owners realize, with cold rubber becoming harder and less shock-absorbing while hot rubber becomes softer and more prone to permanent equipment indentation.

Which flooring option offers better durability and longevity?

Rubber flooring typically provides 10-15 years of service life under heavy commercial use, while quality gym turf offers 6-8 years with proper maintenance, making rubber more cost-effective for high-impact applications.

Durability testing reveals significant differences between the two materials. Rubber flooring withstands compression testing up to 2,000 pounds per square inch without permanent deformation. Quality gym turf, designed for functional training rather than impact absorption, shows performance degradation under loads exceeding 500 pounds per square inch.

Long-term wear patterns develop differently in each material. Rubber flooring may show surface scuffing and color fading but maintains its structural integrity throughout its service life. Turf flooring maintains its appearance better initially but may experience fiber loss or backing separation in extremely high-traffic areas.

Environmental factors affect longevity differently for each material. UV exposure damages turf fibers more than rubber compounds, making rubber better for facilities with significant natural lighting. However, rubber can develop cracking in extremely dry conditions, while turf remains stable across wider humidity ranges.

Lifespan varies significantly by application type. Heavy weight training areas see rubber lasting 12-15 years while turf is not recommended for these applications. Functional training zones show rubber performing for 10-12 years compared to turf’s 6-8 years. Light cardio and stretching areas allow rubber to exceed 15 years while turf provides 8-10 years of service. Sled and agility training areas show rubber lasting 8-10 years with turf providing 6-8 years of reliable performance. Warranty coverage reflects manufacturer confidence, with rubber warranties typically covering 10-15 years against defects while turf warranties focus on 6-year fiber retention.

How do maintenance requirements compare between turf and rubber?

Turf requires daily vacuuming and periodic fiber brushing but resists staining, while rubber needs daily mopping with commercial disinfectants and periodic deep cleaning to prevent odor buildup.

Daily maintenance routines differ significantly between the two surfaces. Turf maintenance involves dry cleaning methods – vacuuming to remove debris and occasional brushing to maintain fiber orientation. This process takes 10-15 minutes for a 1,000 square foot area and requires minimal water or chemicals.

Rubber maintenance emphasizes wet cleaning with disinfectant solutions. Daily mopping removes sweat, bacteria, and odors that can penetrate rubber surfaces. This process requires 20-30 minutes for the same area and involves chemical costs and proper disposal procedures.

Deep cleaning schedules vary based on surface type and usage patterns. Turf deep cleaning involves steam cleaning or extraction methods every 3-6 months. Rubber deep cleaning may require specialized equipment and techniques on a monthly basis in high-use areas.

Annual maintenance costs show significant differences between surfaces. Turf daily cleaning costs approximately $200 annually in vacuum wear, while rubber requires $800 in chemicals and labor. Equipment investment shows turf needing $300 for vacuums and brushes compared to rubber’s $600 for mops and chemicals. Deep cleaning costs $400 for turf’s quarterly professional service versus $1,200 for rubber’s monthly deep cleaning requirements. Stain removal averages $100 annually for turf spot treatments compared to $300 for rubber’s specialized products. Time investment differs with turf requiring 30 minutes daily versus rubber’s 45 minutes daily maintenance routine.

What are the cost differences in initial investment and long-term upkeep?

Initial turf installation costs $8-15 per square foot including materials and labor, while rubber flooring ranges from $12-25 per square foot, but rubber’s longer lifespan often provides better total cost of ownership.

Material costs represent the largest portion of initial investment. Quality gym turf materials cost $4-8 per square foot, while rubber flooring materials range from $6-15 per square foot depending on thickness and quality specifications. Premium options in both categories can exceed these ranges significantly.

Installation labor costs vary based on complexity and local market conditions. Turf installation typically costs $3-6 per square foot due to simpler preparation requirements. Rubber installation costs $5-12 per square foot because of more extensive subfloor preparation and specialized installation techniques.

Subfloor preparation adds variable costs that many gym owners underestimate. Turf installation may require minimal preparation if the existing floor is level and clean. Rubber installation often requires moisture barriers, leveling compounds, and primer applications that can add $2-5 per square foot.

Ten-year total cost analysis for 1,000 square feet shows initial installation costs of $12,000-15,000 for turf versus $18,000-25,000 for rubber. Annual maintenance costs $1,000 for turf compared to $2,900 for rubber. Mid-life replacement adds $12,000 for turf in year 6 while rubber requires no replacement. Total 10-year costs range from $34,000-39,000 for turf versus $47,000-54,000 for rubber, with variations based on specific applications. Hidden costs include climate control during turf installation adding $500-1,000, while rubber may need specialized disposal adding $1-3 per square foot for removal.

Which surface provides superior safety and injury prevention?

Both surfaces excel in different safety aspects – turf prevents friction burns and provides natural movement feel, while rubber offers superior impact protection and slip resistance in dry conditions.

Impact absorption creates the most significant safety difference between surfaces. Rubber flooring can absorb dropped weight impacts up to 500 pounds without transferring dangerous forces to joints or subfloors. Turf provides minimal impact protection, making it unsuitable for areas where weights might be dropped.

Slip resistance varies by conditions and surface texture. Dry turf provides excellent traction through fiber grip characteristics. Dry rubber also offers good traction through surface texturing. However, wet conditions reverse this relationship – turf maintains traction while rubber can become slippery.

Joint stress during extended use differs between surfaces. Turf’s natural cushioning reduces knee and back stress during floor exercises and extended training sessions. Rubber’s firmer surface provides better stability for heavy lifting but may increase joint stress during prolonged floor work.

Safety performance varies by exercise type. Weight training requires rubber’s excellent impact absorption while turf provides minimal protection. Floor exercises benefit from turf’s friction burn reduction while rubber can cause skin irritation. Dynamic movement works well on both surfaces with turf providing natural traction and rubber offering stable support. High-impact training favors rubber’s superior impact protection over turf’s limited shock absorption. Emergency response considerations favor rubber’s smooth surface for easier equipment movement, while turf fibers might impede wheelchair or gurney access. Health safety depends on cleaning capabilities, with rubber’s non-porous surface allowing thorough disinfection while turf’s fiber construction may harbor bacteria in high-moisture conditions.

How do both options perform in terms of noise reduction and comfort?

Turf provides superior comfort for floor exercises and moderate sound dampening, while rubber excels at impact noise reduction and provides stable support for weight training activities.

Sound dampening characteristics serve different acoustic needs. Turf absorbs ambient noise through fiber construction, reducing the echo and reverberation common in large gym spaces. This creates a more comfortable acoustic environment for classes and personal training sessions.

Rubber flooring excels at impact noise reduction, preventing the sharp sounds of dropped weights from transmitting through building structures. In multi-tenant buildings, this impact isolation prevents noise complaints that could threaten facility operations.

Comfort during extended use varies significantly between surfaces. Turf’s natural cushioning allows comfortable floor exercises without additional padding. Members can perform yoga, stretching, and bodyweight exercises directly on the surface without discomfort.

Performance ratings on a 1-10 scale show impact noise reduction favoring rubber at 9 versus turf’s 4, making rubber essential for weight areas. Ambient sound absorption favors turf at 7 compared to rubber’s 5, making turf better for quiet zones. Floor exercise comfort strongly favors turf at 9 versus rubber’s 4, making turf ideal for mat work. Standing comfort shows similar performance with rubber at 7 and turf at 6. Temperature comfort favors turf at 8 compared to rubber’s 6, as turf feels warmer to the touch. Thermal comfort affects year-round member experience, with turf maintaining warmth for barefoot activities while rubber can feel cold in winter months.

When should gym owners choose turf over rubber flooring?

Choose turf for functional training zones, agility areas, and stretching spaces where comfort and natural movement feel matter more than impact protection from dropped weights.

Functional training areas benefit most from turf installation. Sled pushes, bear crawls, and agility ladder work perform better on turf surfaces that provide consistent traction without causing friction burns. The natural feel helps athletes maintain proper form during complex movement patterns.

Budget-conscious installations may favor turf in specific applications. While rubber provides longer lifespan, turf’s lower initial cost allows gym owners to install premium surfaces in targeted areas rather than compromising with lower-grade materials throughout the facility.

Member demographics influence surface selection significantly. Facilities serving athletes who train outdoors often prefer turf because it replicates familiar movement conditions. Boot camp and military-style training programs specifically benefit from turf’s outdoor training simulation.

Ideal turf applications vary by facility type. Functional training studios benefit from turf’s natural movement feel across 80% of floor space. Athletic performance centers use turf in agility and conditioning areas for sport-specific training. CrossFit boxes install turf in designated functional zones for sled work and floor exercises. Personal training studios choose turf for mat work and stretching areas to maximize client comfort. Space limitations may favor turf in smaller facilities where versatility matters more than specialized performance, as turf provides adequate performance across multiple exercise types while rubber’s specialization may be excessive in facilities under 2,000 square feet.

What types of fitness facilities work best with rubber surfaces?

Powerlifting gyms, commercial fitness centers with heavy weight training, and multi-use facilities requiring maximum durability should prioritize rubber flooring for its superior impact protection and longevity.

Commercial fitness centers with diverse membership require rubber’s versatility and durability. High-volume facilities operating 16+ hours daily need surfaces that maintain performance characteristics regardless of usage intensity. Rubber provides consistent traction, impact absorption, and cleaning capabilities that support commercial operations.

Powerlifting and strength training facilities absolutely require rubber flooring in lifting areas. The ability to safely handle dropped barbells, weight plates, and heavy dumbbells makes rubber essential for serious strength training operations. No alternative surface provides adequate protection for this application.

Multi-tenant buildings benefit from rubber’s sound dampening characteristics. Impact noise isolation prevents complaints from neighboring tenants that could force facility closure. The superior acoustic properties justify rubber’s higher cost in commercial building applications.

Facility types that favor rubber include commercial gyms requiring maximum durability across all zones, powerlifting gyms needing rubber throughout lifting areas, hotel fitness centers where low maintenance and professional appearance matter, corporate fitness facilities requiring minimal operational disruption, and rehabilitation centers needing surfaces that support medical equipment and safety protocols. Insurance and liability considerations often mandate rubber flooring in commercial facilities, as many policies specify minimum impact absorption requirements that only rubber can meet reliably.

Can you combine both flooring types in the same gym space?

Combining turf and rubber creates optimal performance by using each material where it excels – rubber for weight training zones and turf for functional training areas, connected with professional transition strips.

Zone-based design represents the most effective approach to gym flooring. Weight training areas require rubber’s impact protection, while functional training spaces benefit from turf’s comfort and traction characteristics. This targeted approach maximizes performance while controlling costs.

Transition planning becomes critical when combining surfaces. Professional transition strips prevent trip hazards and create clean visual boundaries between zones. The transition strips must accommodate the height difference between surfaces while providing smooth movement for equipment and members.

Installation sequencing affects both cost and timeline when combining materials. Installing both surfaces simultaneously reduces labor costs and minimizes facility downtime. However, different curing requirements may extend the timeline compared to single-surface installations.

Successful combination strategies include creating distinct training zones with appropriate surface selection, using professional transition strips to prevent safety hazards, coordinating installation timing to minimize facility closure, planning equipment placement to work with surface characteristics, and designing visual flow that guides member movement between zones. Maintenance protocols must address both surface types with appropriate cleaning schedules and techniques. Member education helps prevent misuse of surfaces, such as dropping weights on turf areas or expecting rubber comfort during extended floor work.

Which option works better for different workout zones and equipment areas?

Free weight areas require rubber for impact protection, functional training zones need turf for comfort and traction, while cardio areas can use either material based on aesthetic and budget preferences.

Free weight and Olympic lifting zones absolutely require rubber flooring rated for heavy impact loads. Areas where barbells, dumbbells, and weight plates are regularly dropped need surfaces capable of absorbing 500+ pound impacts without damage. Rubber thickness should range from 15-25mm in these zones.

Functional training areas perform best with turf surfaces that provide natural movement feel and comfort during floor exercises. Sled pushes, agility work, and bodyweight training benefit from turf’s consistent traction and cushioning characteristics. The 15-20mm pile height works well for most functional training applications.

Cardio equipment areas offer flexibility in surface selection. Both rubber and turf can support cardio equipment effectively, making the choice dependent on aesthetic preferences, budget constraints, and integration with surrounding zones.

Equipment-specific recommendations include Olympic lifting platforms requiring 20-25mm rubber for maximum impact protection, functional training sleds working best on consistent turf surfaces, stretching and yoga areas benefiting from turf’s natural cushioning, heavy dumbbell areas needing rubber’s impact absorption, and group fitness studios choosing based on primary activities. Traffic flow considerations affect zone boundaries, with high-traffic transition areas potentially favoring rubber’s durability over turf’s comfort characteristics. Sound control requirements may override other factors in multi-tenant buildings where noise complaints threaten operations.

What installation challenges might arise with each flooring type?

Turf installation requires precise temperature control and humidity management during adhesive curing, while rubber installation demands extensive subfloor preparation and specialized seaming techniques.

Turf installation challenges center around environmental control and adhesive performance. Temperature must remain between 18-27°C for 48 hours before and after installation. Humidity levels above 85% can prevent proper adhesive bonding, leading to premature failure that may not appear for months after installation.

Subfloor preparation requirements differ significantly between materials. Turf installation requires completely level surfaces with minimal tolerance for variation. Any irregularities in the subfloor will telegraph through the turf surface, creating visible imperfections and potential wear patterns.

Rubber installation presents different challenges related to material handling and seaming. Rubber rolls are heavier and more difficult to position than turf materials. Professional seaming equipment is required to create invisible joints between rubber sections.

Specific installation challenges include turf requiring 48-hour temperature acclimation before installation, adhesive curing being sensitive to humidity levels, subfloor must be perfectly level with minimal variation tolerance, rubber needing specialized tools for seaming and edge work, heavy material requiring additional labor for positioning, and moisture barriers being essential for concrete subfloors. Timing coordination becomes critical when combining materials, as different curing schedules may extend project timelines. Access limitations in existing facilities may require material cutting and reassembly that affects installation quality and warranty coverage.

How do climate and humidity affect both turf and rubber performance?

High humidity above 85% can compromise turf adhesive bonding during installation, while temperature extremes affect rubber flexibility and performance characteristics more than turf stability.

Humidity control during turf installation determines long-term performance success. Adhesive systems require specific moisture conditions to achieve proper bonding with the subfloor. High humidity prevents complete curing, leading to adhesive failure months after installation when the surface begins lifting at edges or seams.

Temperature fluctuations affect rubber performance more significantly than turf. Cold conditions make rubber harder and less shock-absorbing, while hot conditions can make rubber softer and prone to permanent indentation from equipment. Turf maintains more consistent performance across temperature ranges.

Moisture exposure during operation creates different challenges for each material. Turf maintains traction when wet but may develop odor issues if moisture penetrates the backing system. Rubber becomes slippery when wet but cleans easily once dried.

Climate-specific performance factors include turf installation requiring humidity below 85% for proper adhesive curing, temperature control being critical during 48-hour installation window, rubber becoming harder and less shock-absorbing in cold conditions, hot conditions making rubber softer and prone to equipment indentation, and moisture creating slip hazards on rubber while turf maintains traction. HVAC system design must account for these requirements, potentially increasing operational costs in extreme climates. Seasonal performance variations may require adjusted maintenance protocols and member safety education.

What cleaning and sanitization protocols work best for each surface?

Turf cleaning focuses on dry methods like vacuuming and occasional steam cleaning, while rubber requires daily wet mopping with commercial disinfectants and periodic deep cleaning to prevent odor and bacteria buildup.

Turf cleaning protocols emphasize dry cleaning methods that preserve fiber integrity. Daily vacuuming removes surface debris and prevents grinding particles that can damage fibers over time. Steam cleaning every 3-6 months provides deep sanitization without introducing excessive moisture that could affect backing adhesion.

Rubber cleaning requires wet methods with commercial disinfectants to address sweat, bacteria, and odor absorption. Daily mopping with EPA-approved gym disinfectants removes surface contamination and prevents bacterial growth that can create health hazards and persistent odors.

Chemical compatibility becomes critical for both surfaces. Turf can be damaged by harsh chemicals that dissolve polyethylene fibers or affect backing materials. Rubber can withstand stronger disinfectants but may be damaged by petroleum-based products or certain solvents.

Daily cleaning protocols include turf requiring vacuuming with commercial equipment to remove debris, occasional brushing with synthetic bristles to maintain fiber orientation, spot cleaning with mild detergent solutions for stains, and rubber needing daily mopping with commercial disinfectants, immediate cleanup of spills to prevent staining, and weekly deep cleaning in high-use areas. Equipment requirements differ significantly, with turf needing commercial vacuum cleaners and synthetic brushes while rubber requires mop systems, chemical storage, and potentially steam cleaning equipment. Staff training must address chemical handling safety, proper dilution ratios, and surface-specific techniques to prevent damage and ensure effective sanitization.

Which flooring choice offers better ROI for different gym business models?

Budget-conscious functional training studios see better ROI with turf due to lower initial costs and targeted performance, while high-volume commercial gyms benefit from rubber’s longer lifespan and reduced liability exposure.

Functional training studios operating on tight budgets benefit from turf’s lower initial investment and targeted performance characteristics. The reduced upfront cost allows owners to invest saved capital in equipment and marketing while still providing premium surface performance in functional training zones.

Commercial fitness centers with diverse membership and high usage volumes see better long-term ROI with rubber flooring. The longer lifespan, predictable maintenance costs, and reduced liability exposure justify the higher initial investment through improved operational efficiency and risk management.

Membership retention correlates differently with surface choice depending on facility focus. Studios emphasizing functional training see higher member satisfaction with turf surfaces, while traditional gyms with heavy weight training benefit from rubber’s professional appearance and performance capabilities.

Business model considerations include boutique studios benefiting from turf’s lower initial investment and member comfort features, commercial gyms seeing better ROI from rubber’s durability and professional appearance, franchise operations preferring rubber’s standardized maintenance and longer replacement cycles, and personal training facilities choosing based on primary service offerings. Insurance and liability factors affect ROI calculations, as rubber flooring may qualify for lower liability insurance rates due to superior safety characteristics. Member acquisition costs may be affected by facility appearance and performance, making the flooring choice a marketing consideration as well as an operational decision.