Before selecting and fitting your rubber gym flooring, understand your activity needs, flooring thickness, material quality, and format (rolls, tiles, or gym floor mats). Proper subfloor preparation and acclimation are key for a lasting installation of your chosen gym floor.

Choosing the right rubber gym flooring is a big decision. As a production manager in a rubber floor factory, I’ve seen it all. It’s not just about picking a color; it’s about safety, durability, and performance. Your home gym flooring or commercial gym flooring needs to withstand everything from dropped dumbbells in the weight room flooring area to high-intensity interval training. Think about the specific activities. Will there be heavy weights? High-impact cardio? Or maybe it’s a quieter yoga space needing fitness mat like qualities? The type of gym floor you need, whether it’s rubber gym mats, gym floor tiles, or gym flooring rolls, depends heavily on this. We always tell our customers that the foundation of a great gym starts from the ground up, with the best gym flooring they can invest in. Getting this right means a safer, more effective workout environment and fewer headaches down the line with your gym matting.

Thinking about your gym’s future can feel overwhelming, but it doesn’t have to be. Once you’ve considered these initial points, you’re already on your way to making a smart choice. But what about the nitty-gritty details that ensure your flooring performs as expected for years to come?

How Can You Tell If a Rubber Floor’s Abrasion Resistance Meets Standards?

A rubber floor’s abrasion resistance is often indicated by standardized test results (e.g., Taber Abrasion Test). Look for specifications from the gym rubber flooring company or ask for data sheets that confirm it meets industry benchmarks for durability.

In our factory, testing for abrasion resistance is a critical step. We want to ensure our rubber gym floor mats and gym flooring tiles can handle constant foot traffic, shuffling equipment, and the general wear and tear of a busy gym. A good quality rubber gym floor shouldn’t scuff, tear, or wear down prematurely.

Understanding Abrasion Tests

We typically use methods like the Taber Abrasion Test. This involves a weighted abrasive wheel rotating over the gym mat flooring surface for a set number of cycles. The amount of material lost is then measured. Lower material loss indicates higher abrasion resistance. When you’re looking at mats for gym use, especially for high-traffic zones or areas where equipment like sleds might be pushed, this is a key factor. Always ask suppliers for these test results or certifications. This is particularly important for commercial gym flooring where the intensity of use is much higher than a typical home gym flooring setup. A gym matt that wears out quickly isn’t just an aesthetic issue; it can become a safety hazard.

It’s clear that abrasion resistance is key for longevity. But what about the immediate impact on the user during their workout? This brings us to another vital characteristic.

Why Is Shock Absorption in Rubber Gym Flooring Crucial for Joint Protection?

Shock absorption in rubber gym flooring is vital because it cushions impact, reducing stress on joints like knees and ankles during high-impact exercises. This helps prevent injuries and enhances comfort for anyone using the gym floor mats or workout floor mats.

As someone who oversees the production of gym floors, I can tell you that shock absorption is one of the primary reasons people choose rubber. When you’re jumping, running, or even just doing bodyweight exercises, your joints take a beating. Good quality rubber gym mats act like a giant fitness mat, absorbing a significant portion of that impact.

How Rubber Provides Protection

The inherent elasticity of rubber is what makes it so effective. For instance, our rubber gym floor mats are designed with specific densities to optimize this. Thicker gym flooring tiles or gym flooring rolls generally offer better shock absorption, which is why they’re recommended for areas with plyometrics or heavy lifting. Think about dropping a heavy dumbbell; you want the gym floor matting to absorb the shock, protecting both the subfloor and the dumbbell, not to mention reducing noise. For a home gym flooring where you might be working out barefoot or in minimal shoes, this joint protection from your exercise mats for home gym becomes even more important for a comfortable and safe session.

Protecting joints is a major plus. But what about areas where the impact isn’t just from bodies, but from heavy equipment?

What Type of Rubber Flooring Is Best for Free Weight Areas and How Can It Prevent Injuries?

For free weight areas, high-density, thick rubber gym flooring (often 3/4 inch or thicker gym floor tiles or rubber mats for gym) is best. It protects the subfloor from dropped weights and prevents injuries by providing a stable, shock-absorbent surface.

In my experience, the free weight zone is where your gym floor takes the most punishment. You need weight room flooring that’s up to the task. We produce super-dense rubber gym floor mats and thick interlocking gym mats specifically for these areas. These aren’t your average workout floor mats; they are engineered to handle repeated impacts from heavy barbells and dumbbells.

Preventing Injuries in Weight Zones

The right flooring for gym floors in these areas does several things:

- Subfloor Protection: Prevents damage to the concrete or wood underneath when weights are accidentally (or intentionally) dropped. A cracked subfloor is a huge, costly problem.

- Equipment Protection: Cushions the blow for your expensive weights, reducing wear and tear on them.

- User Safety: Provides a stable, non-slip surface. Good gym matting ensures users have secure footing when lifting heavy, reducing the risk of slips and falls. The shock absorption also lessens the impact transferred back to the user if a weight is dropped near them.

We often recommend solid rubber gym floor tiles rubber for easy replacement if one section gets damaged, though our gym flooring rolls also offer excellent protection with fewer seams.

So, you’ve figured out the type of flooring. Now, how do you get it from our factory floor to your gym floor?

Can You Install Rubber Roll Flooring Yourself or Should You Hire a Professional Team?

While gym flooring rolls can be DIY-installed, especially for smaller home gym flooring projects if you’re handy, professional installation is often recommended for large or commercial gym flooring to ensure a seamless, durable finish and proper adhesion.

This is a common question we get. Rubber gym flooring rolls offer a fantastic, almost seamless look, which is great for large spaces. However, they can be heavy and a bit unwieldy. If you’re talking about a small garage gym mat area, you might manage. But for an entire fitness room flooring using rolls, it’s a different story.

DIY vs. Professional

Here’s a breakdown:

- DIY: Possible for smaller areas or if you have experience. You’ll need patience, precision for cutting, and possibly a helper for maneuvering the heavy gym flooring rubber. Tools like a very sharp utility knife and a long straight edge are essential.

- Professional: For larger installations, or if you want the best gym flooring outcome, pros are the way to go. They have experience with subfloor prep, adhesive application (if needed), and cutting complex angles. This ensures your rubber flooring gym investment looks and performs its best for years. They understand how the material behaves, which can prevent issues later.

At our gym rubber flooring company, we often provide detailed installation guides, but we always advise customers to consider the scale and complexity before deciding.

Whether you DIY or hire pros, avoiding common pitfalls is key. What are those, and how can you sidestep them?

What Are the Common Installation Mistakes and How Can You Prevent Curling or Peeling?

Common mistakes include poor subfloor prep, not acclimating the rubber gym flooring, incorrect adhesive use, or not leaving expansion gaps. Prevent curling/peeling by ensuring a clean, level subfloor, allowing acclimation, using the right adhesive, and following manufacturer guidelines.

I’ve seen a few installation jobs that didn’t go as planned, and it’s usually down to a few common errors. These can affect any type of gym floor, from gym floor tiles to rolls. Curling edges or peeling rubber gym mats are not just unsightly; they can be tripping hazards.

Top Mistakes and Prevention:

- Skipping Subfloor Prep: The subfloor must be clean, dry, and perfectly level. Any debris or moisture can compromise adhesion for your gym floor matting.

- Ignoring Acclimation: Rubber expands and contracts with temperature. Lay out your gym flooring mats or rolls in the room for 48-72 hours before installation to acclimate. This prevents buckling or gaps later.

- Wrong Adhesive/Application: If you’re gluing down your rubber gym floor, using the manufacturer-recommended adhesive and applying it correctly (not too much, not too little) is crucial.

- No Expansion Gaps: Especially for larger areas or floating installations of interlocking gym mats, leaving a small gap around the perimeter allows for natural expansion, preventing curling.

Following our guidelines carefully can save a lot of trouble and ensure your floor mats for gym stay put.

A good installation starts with what’s underneath. How do you ensure your base is ready?

How Do You Know If Your Subfloor Is Suitable for Rubber Roll Installation?

A suitable subfloor for rubber gym flooring rolls must be clean, dry, structurally sound, and level. Concrete is ideal, but wood or existing tile can work if properly prepared. Test for moisture and levelness before installing your gym floor.

Before any rubber gym floor goes down, especially our heavy-duty gym flooring rolls, the subfloor needs careful assessment. As a manufacturer, we stress this because the best gym rubber flooring can fail if the base isn’t right.

Subfloor Checklist:

- Cleanliness: Free of dust, dirt, grease, paint, or old adhesives. Any contaminants can prevent proper bonding of your gym matting.

- Dryness: Moisture is a major enemy. For concrete, a moisture test (e.g., calcium chloride test) is recommended. High moisture can lead to adhesive failure or mold growth under your rubber flooring gym.

- Levelness: The subfloor should be flat. Any significant dips or bumps will show through the rubber or create uneven wear on your workout flooring. Use a leveling compound if necessary.

- Structural Soundness: Ensure the subfloor can handle the weight of the rubber and the activities. This is particularly important for upper floors or basement gym flooring over less stable surfaces.

A little extra time spent on subfloor prep for your floor gym makes a huge difference in the long run.

Once the subfloor is ready, the next big question is about the rubber itself. Specifically, how thick should it be?

What Thickness of Rubber Flooring Is Recommended for Different Gym Zones?

For general fitness/cardio areas, 8mm rubber gym flooring is common. For weight room flooring with heavy free weights, 12mm to 3/4 inch (19mm) or thicker gym floor tiles or rubber mats for gym are recommended for optimal protection and shock absorption.

We produce rubber gym flooring in a range of thicknesses because different areas of a gym have different needs. It’s not a one-size-fits-all solution when it comes to gym floors. For example, the needs of a yoga studio are vastly different from a CrossFit box.

Thickness Guide:

- Light Activity Zones (Yoga, Cardio Machines): 6mm to 8mm (approx 1/4 to 5/16 inch). This provides comfort, some shock absorption for fitness mat areas, and protection for fitness equipment mat placements.

- Functional Training / Light Weights: 8mm to 10mm (approx 5/16 to 3/8 inch). Good for areas with kettlebells, dumbbells up to moderate sizes, and bodyweight circuits. Many home gym flooring setups use this.

- Heavy Weightlifting / CrossFit: 12mm to 19mm (1/2 to 3/4 inch), or even thicker for extreme use. These heavy-duty gym floor tiles rubber or rubber gym floor mats are essential to protect the subfloor and equipment in dedicated weight room flooring areas. We even make mats for weight equipment that are over an inch thick for serious powerlifting.

Choosing the right thickness ensures longevity and safety for your gym matt and users.

Thickness is one aspect of material choice. But what about the type of rubber itself?

What’s the Difference Between SBR and EPDM Rubber and Which Is Better for You?

SBR (Styrene-Butadiene Rubber) is a durable, cost-effective recycled rubber, common in black gym floor mats. EPDM (Ethylene Propylene Diene Monomer) is a synthetic virgin rubber offering vibrant color flecks, UV resistance, and higher durability, often at a higher price for gym flooring tiles.

In our factory, we work with various rubber compounds. SBR and EPDM are two common ones you’ll encounter when looking for rubber gym flooring. SBR is typically made from recycled tires, making it a cost-effective and eco-friendly choice for basic black rubber gym mats and gym floor tiles. It provides excellent durability and shock absorption for most gym floor applications.

SBR vs. EPDM:

| Feature | SBR (Styrene-Butadiene Rubber) | EPDM (Ethylene Propylene Diene Monomer) |

|---|---|---|

| Source | Mostly recycled (e.g., car tires) | Virgin synthetic rubber |

| Color | Primarily black; some color flecks possible | Wide range of vibrant colors possible |

| Durability | Good to excellent | Excellent to superior |

| UV Resistance | Fair; can fade/degrade in direct sun | Excellent; good for outdoor/sunny areas |

| Odor | Can have a noticeable rubber odor initially | Typically lower odor |

| Cost | More budget-friendly | More premium priced |

EPDM is often used as the colored flecks in SBR gym flooring mats to add aesthetic appeal, or as the top layer in premium gym flooring rubber products. If you need specific colors, want enhanced wear resistance, or if the fitness room flooring will be exposed to a lot of sunlight, EPDM might be a better, albeit more expensive, choice. For most indoor gyms and mats, SBR offers a fantastic balance of performance and value.

The source material definitely impacts quality. This leads to a common concern about budget options.

Why Do Cheap Rubber Floors Fall Apart Over Time — Is It a Material Issue?

Yes, cheap rubber gym flooring often degrades due to lower-quality recycled materials, inconsistent binder agents, or insufficient density. This can lead to crumbling, cracking, or premature wear of the gym floor mats, making them a poor long-term investment.

"You get what you pay for" often holds true with rubber gym floors. While budget-friendly options exist, extremely cheap gym mats for sale can be a red flag. From my perspective as a production manager, the quality of the raw materials and the manufacturing process are paramount.

Reasons for Failure in Cheap Flooring:

- Poor Recycled Material: If the recycled rubber (often SBR from tires) isn’t properly cleaned or processed, it can contain contaminants that weaken the final gym matt.

- Inferior Binder: The urethane binder that holds the rubber granules together is crucial. Low-quality or insufficient binder can cause the gym floor tiles to crumble or "shed" granules over time.

- Low Density: Cheaper workout floor mats might be less dense. While this makes them lighter, it also means less material, reduced durability, and poorer shock absorption.

- Inconsistent Manufacturing: Lack of quality control can lead to variations in thickness and density within the same batch of mats at the gym.

Investing a bit more in great mats from a reputable gym rubber flooring company generally means better raw materials and stricter manufacturing standards, resulting in a rubber floor mat gym solution that lasts.

Durability is one thing, but day-to-day upkeep is another. How easy is it to keep these floors looking good?

How Easy Is It to Clean Rubber Flooring and What Cleaning Mistakes Should You Avoid?

Rubber gym flooring is generally easy to clean with regular vacuuming and mopping using a pH-neutral cleaner. Avoid harsh solvents, excessive water, or abrasive scrubbers, as these can damage the rubber gym mats or gym floor tiles over time.

One of the benefits of quality rubber gym flooring is its relatively low maintenance. In our production, we aim for surfaces that are non-porous or minimally porous to make cleaning easier. A clean gym floor is essential for hygiene and a pleasant workout environment.

Cleaning Do’s and Don’ts for your gym matting:

Do:

- Vacuum or sweep regularly to remove dust, dirt, and debris.

- Mop with a damp (not soaking wet) mop using a pH-neutral cleaner specifically designed for rubber floors or a mild detergent solution.

- Spot clean spills promptly.

Don’t: - Use harsh chemicals like solvents, oil-based cleaners, or acidic/alkaline detergents. These can break down the rubber in your workout rubber mats.

- Flood the floor with excessive water, especially with interlocking gym mats, as water can seep underneath.

- Use abrasive scouring pads or steel wool, which can scratch and damage the surface of your floor mats for fitness.

Following these simple guidelines will keep your gym flooring rubber looking its best for years.

Cleanliness is tied to hygiene. What about other potential issues like smells or mold?

Does Rubber Flooring Absorb Odors or Grow Mold — Especially in Humid Areas?

Most quality rubber gym flooring is non-porous or low-porosity, resisting odor absorption and mold growth. However, prolonged moisture exposure, especially under gym floor mats in humid areas without proper cleaning, can potentially lead to issues.

This is a valid concern, especially for basement gym flooring or gyms in humid climates. The distinctive smell of new rubber gym mats is usually due to off-gassing of volatile organic compounds (VOCs) from the manufacturing process, particularly with SBR rubber. This typically dissipates over a few days or weeks with good ventilation.

Odor and Mold Prevention:

- Quality Matters: Higher quality, denser rubber gym floor materials, and those made with virgin rubber or specific EPDM compounds, tend to have less initial odor and better resistance.

- Ventilation: Good airflow is key, especially when new gym mat flooring is installed, to help any odors dissipate quickly.

- Moisture Control: The biggest factor for mold is moisture. Ensure the subfloor is dry before installation and address any spills on your exercise mats for home gym promptly. For humid areas, ensure good HVAC operation.

- Cleaning: Regular cleaning (as mentioned before) prevents dirt and organic matter buildup that could feed mold if moisture is present.

While no gym floor tile is completely impervious if neglected in a damp environment, well-maintained rubber flooring gym installations rarely have significant issues with persistent odors or mold.

These quality aspects often come with a price tag. Why is there such a range?

Why Do Rubber Flooring Prices Vary So Much — and Is Expensive Always Better?

Rubber flooring prices vary due to material type (virgin EPDM vs. recycled SBR), thickness, density, manufacturing complexity (e.g., intricate gym floor tiles vs. simple gym mats for sale), brand, and origin. Expensive isn’t always better, but extremely cheap options often compromise quality.

As a manufacturer, I see the cost components that go into rubber gym flooring. The price of gym floor mats for garage can be very different from premium commercial gym flooring.

Factors Influencing Price:

- Raw Materials: Virgin rubber (like EPDM) is more expensive than recycled SBR. The quality and processing of recycled rubber also affect cost.

- Thickness & Density: More material means higher cost. Denser rubber gym floor mats use more raw material and are generally more durable.

- Manufacturing Process: Intricate designs for gym flooring tiles, special surface textures, or multi-layer constructions add to production costs.

- Color: Black SBR is typically the cheapest. Adding EPDM color flecks to rubber gym floor products increases the price, with full EPDM color being the most expensive.

- Brand & Origin: Established brands may have higher prices reflecting R&D, quality control, and warranty. Import costs can also play a role.

While a higher price often indicates better materials or more features (like in the best fitness mat), it’s about finding the best value for your specific needs. Don’t just go for the cheapest gym matt without considering its suitability and expected lifespan.

Understanding price variations is one thing, but working within a set financial plan is another.

How Can You Choose the Right Rubber Flooring Within a Limited Budget?

Within a limited budget, prioritize thickness and durability for high-impact areas. Consider good quality SBR recycled rubber gym flooring, look for sales on gym mats for sale, or opt for gym floor tiles to cover specific zones instead of an entire room.

We understand that not everyone has an unlimited budget for their gym floor. The good news is that you can still get effective and durable rubber gym mats or gym flooring tiles without breaking the bank. It’s about making smart choices.

Budget-Friendly Strategies:

- Prioritize Key Areas: If you can’t afford to cover the entire fitness room flooring with premium material, focus on the areas that need it most, like the weight room flooring section, with thicker, more durable mats for weight equipment. Use thinner, more affordable workout floor mats elsewhere.

- SBR Recycled Rubber: This is often the most cost-effective gym flooring rubber. It provides excellent performance for most applications, especially for home gym flooring or garage gym mat setups.

- Tiles Over Rolls: Gym floor tiles rubber can be more budget-friendly as you only buy what you need, and installation can be a DIY job, saving on labor costs. Interlocking gym mats are particularly good for this.

- Look for Sales/Clearance: Keep an eye out for gym mats for sale or discontinued lines from reputable suppliers. You might find great mats at a discount.

It’s about balancing cost with essential performance features for your mat flooring for gym.

Beyond the practical, how can flooring contribute to your gym’s look and feel?

Can Rubber Gym Flooring Be Customized with Logos — and What Are Some Real Examples?

Yes, rubber gym flooring can be customized with logos or designs using methods like waterjet cutting for inlaid EPDM graphics or screen printing. Many commercial gym flooring installations feature prominent brand logos or functional zone markings directly on the gym floor tiles or rolls.

Customization is something we do quite a bit of at our factory. It transforms a generic gym floor into a branded statement. Adding a logo or custom design to your rubber gym floor mats can significantly enhance the look of your facility.

Customization Examples:

- University Gyms: Often feature the school mascot or athletic department logo inlaid in the center of the basketball court’s rubber surround or in the weight room flooring.

- CrossFit Boxes: May have their box logo, lifting platform outlines, or lane markers integrated into their gym matting.

- Boutique Fitness Studios: Might use custom colors or patterns in their gym flooring tiles to match their brand aesthetic.

- Commercial Gym Chains: Frequently have their main brand logo prominently displayed on the gym rubber flooring mat at the entrance or in key training zones.

Techniques like precision waterjet cutting allow for intricate designs using different colored EPDM rubber, creating a very durable and high-end finish. This really makes your gym rubber floor unique.

A custom logo is just one part of the bigger picture. How does the overall design play a role?

How Can Flooring Design Enhance Your Gym’s Professionalism and Brand Identity?

Thoughtful gym floor design, using color, texture, and custom graphics in your rubber gym flooring, can define workout zones, improve traffic flow, reinforce branding, and create a more professional and motivating atmosphere for your gym floors and mats at the gym.

The gym floor is one of the largest visual elements in your facility. As a production manager, I’ve seen how smart gym mat flooring choices can elevate a space from functional to fantastic. It’s not just about picking rubber mats for gym; it’s about creating an experience.

Enhancing Professionalism and Brand:

- Zone Demarcation: Using different colors or types of gym flooring tiles (e.g., thicker rubber gym floor mats for free weights, different color workout floor mats for cardio) can clearly define workout zones. This improves organization and safety.

- Brand Reinforcement: Consistent use of brand colors in your gym flooring rubber and, as mentioned, custom logos, strengthens brand identity.

- Wayfinding: Flooring patterns or color paths can subtly guide members through the gym.

- Atmosphere: The color and texture of your floor gym contribute to the overall mood. Darker colors might feel more intense for a weight room flooring, while brighter colors or wood-look rubber could be used in group fitness areas.

A well-designed fitness room flooring shows attention to detail and professionalism.

Aesthetics are important, but so is the acoustic environment, especially in multi-story buildings.

Can Rubber Flooring Effectively Reduce Noise Between Upstairs and Downstairs Gyms?

Yes, rubber gym flooring, especially thicker varieties, significantly reduces impact noise (like dropped weights or jumping) and vibration transmission between floors. This makes it an excellent choice for upstairs gyms to minimize disturbance to a floor gym or other occupants below.

Noise complaints are a common issue, especially if a gym is located above another business or residential area. The thud of dropped weights or the rumble of treadmills can be very disruptive. This is where the inherent properties of rubber gym flooring shine.

How Rubber Reduces Noise:

Our rubber gym floor mats and gym flooring tiles are designed to absorb impact energy. When a weight is dropped on a thick gym pad or rubber gym floor, a large portion of the sound and vibration is dampened by the rubber itself, rather than being transmitted through the building structure. For example, a 1/2-inch or 3/4-inch gym rubber flooring mat can make a huge difference. This is critical for commercial gym flooring in multi-story buildings. The density and thickness of the workout flooring are key factors in its sound-dampening capabilities. Many clients specifically choose our gym floors to solve noise issues with their downstairs neighbors.

If standard rubber isn’t enough, are there ways to boost this sound dampening?

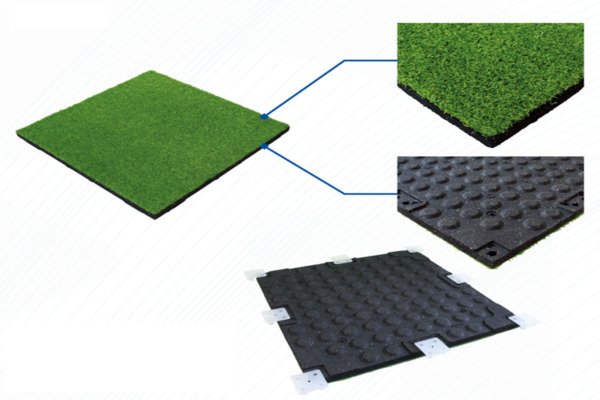

Is It Worth Adding an Acoustic Underlay — Does a Multi-Layer Structure Help?

Yes, adding an acoustic underlay beneath rubber gym flooring can significantly enhance noise and vibration reduction, especially for severe impact noise. A multi-layer system (subfloor, underlay, gym floor mats) is often the best gym flooring solution for maximum sound insulation.

Sometimes, even thick rubber gym flooring might not be enough to fully mitigate noise, especially in buildings with poor inherent sound insulation or for activities involving very heavy impacts (like Olympic lifting on a mat for workout). In these cases, we often recommend an acoustic underlay.

Benefits of Acoustic Underlay:

An acoustic underlay is a specialized layer, often made from rubber crumb, cork, or foam, designed to sit between the subfloor and your primary gym flooring tiles or rolls.

- Enhanced Impact Sound Reduction: It adds another layer of deflection and absorption, significantly cutting down the "thud" that travels through floors.

- Vibration Dampening: It helps to decouple the gym matting from the structural floor, reducing the transmission of vibrations.

- Improved Overall Performance: For the ultimate in noise control, a multi-layer system—concrete subfloor, acoustic underlay, then your chosen rubber gym floor—is highly effective. This is particularly relevant for premium commercial gym flooring or fitness room flooring located directly above sensitive areas. While it adds to the cost, the peace and quiet it brings can be well worth it, preventing issues with neighbors or other tenants.

Finally, a critical consideration for any material we bring into our spaces: its environmental impact and safety.

Is Recycled Rubber Flooring Eco-Friendly — and Is It Safe for Human Health?

Recycled rubber gym flooring, often made from scrap tires (SBR rubber), is eco-friendly by diverting waste from landfills. Reputable manufacturers ensure their gym floor mats meet safety standards for VOC emissions and are safe for human health in home gym flooring and commercial settings.

This is a question we take very seriously at our gym rubber flooring company. The majority of black rubber gym mats and gym floor tiles are made from recycled SBR rubber, primarily from end-of-life vehicle tires. This is a fantastic way to give these materials a second life and reduce landfill waste, making it an environmentally conscious choice for your gym floor matting.

Safety and Eco-Friendliness:

- Eco-Friendly: Millions of tires are diverted from landfills each year to create products like rubber gym floors. This reduces waste and the need to manufacture virgin rubber.

- Safety Standards: As manufacturers, we adhere to strict production processes. We ensure that our recycled rubber mats for gym are thoroughly cleaned and processed to remove contaminants. Reputable companies test their products for volatile organic compounds (VOCs) and ensure they meet indoor air quality standards (like FloorScore® certification). This makes them safe for exercise mats for home gym use, schools, and commercial gym flooring.

- Durability: The longevity of rubber flooring gym products also contributes to their sustainability. A floor that lasts for many years doesn’t need frequent replacement.

Always look for products from manufacturers who are transparent about their materials and safety testing, ensuring your workout matt is both green and safe.

Making the right choice involves many factors, but hopefully, this detailed look helps you on your way.

Conclusion

Choosing and installing rubber gym flooring requires careful thought on use, material, and installation. Prioritize safety, durability, and proper setup for a lasting, effective workout surface.