TL;DR: Быстрый ответ

Если два коврика имеют одинаковую толщину, но на ощупь отличаются, то "жесткий", скорее всего, имеет более высокую плотность или вулканизированное покрытие (для устойчивости). "Мягкий" коврик, скорее всего, имеет меньшую плотность или сетчатое дно (для амортизации). Ни то, ни другое не является "плохим" - они служат для разных видов спорта. Жесткие - для поднятия тяжестей, мягкие - для прыжков и суставов.

Является ли плотность основной причиной разницы в ощущениях?

Первый параграф:

Да. Плотность (измеряется в кг/м³) является основным фактором. Более высокая плотность означает, что гранулы резины плотно упакованы с минимальным количеством воздуха, создавая жесткую поверхность, как у автомобильных шин. При меньшей плотности между гранулами остаются внутренние воздушные зазоры, что позволяет коврику сжиматься и ощущаться "пористым", как беговая дорожка.

Глубокое погружение:

Давайте разберемся в физике того, что происходит под вашими ногами. На нашей фабрике плотность контролируется соотношением массы резины и объема формы. Когда мы производим Маты высокой плотности (прибл. 950 кг/м³ - 1100 кг/м³)Мы сжимаем огромное количество гранул в форме. Частицы прижимаются друг к другу так плотно, что у них физически не остается места для движения. В результате твердость по Шору А составляет 70-80 единиц, что позволяет получить пол, по ощущениям не уступающий бетонному, но устойчивый к скольжению.

С другой стороны, а Маты стандартной плотности (прибл. 800 кг/м³) сконструирована с использованием "микропустот". Мы используем меньше сырья при той же высоте формы, намеренно оставляя микроскопические воздушные карманы между резиновой крошкой. Когда вы наступаете, резина не просто поддерживает вас, она вытесняется в эти пустые пространства. Это сжатие и есть та "мягкость", которую вы чувствуете. Это не недостаток, это механический амортизатор, предназначенный для снижения силы удара на ваши суставы.

Переход:

Плотность объясняет внутреннее давление, но фактические ингредиенты, которые мы смешиваем в замесе - в частности, размер резиновой крошки - также сильно меняют текстуру поверхности.

Имеет ли значение размер резиновых гранул?

Первый параграф:

Абсолютно верно. По размеру резиновая крошка напоминает заполнитель в бетоне. Мелкие, похожие на пыль гранулы создают гладкую, жесткую и плотную поверхность. Более крупные гранулы создают структуру с более естественными зазорами и гибкостью, в результате чего коврик кажется более мягким и амортизирующим.

Глубокое погружение:

Подумайте о разнице между песочницей, наполненной мелким песком, и песочницей, наполненной гравием. Мелкий песок плотно укладывается, а гравий сдвигается и перемещается. В резиновых напольных покрытиях, Мелкие гранулы (часто используемые в верхнем 1-2-миллиметровом "износостойком слое") идеально сочетаются друг с другом. Благодаря большой площади поверхности они впитывают больше полиуретанового связующего (клея), создавая композитный слой, который является очень жестким, гладким и легко очищается. Именно поэтому тренажерная плитка премиум-класса часто кажется более твердой на ощупь.

Крупные гранулыобычно используются в базовом слое, имеют неравномерную структуру и крупнозернистую структуру. Они не могут плотно прилегать друг к другу. Связующее вещество создает гибкие мостики между этими крупными кусками, формируя "скелет", который можно сгибать и скручивать. Если взять в руки образец, полностью состоящий из крупных гранул, его можно согнуть пополам. Если взять в руки образец, состоящий из мелкого порошка, он может сломаться или вообще не поддаться изгибу. Рецепт" размера гранул - это то, что регулирует гибкость конечного продукта. (Чтобы понять, какие материалы лежат в основе этих рецептов, ознакомьтесь с нашим подробным руководством по Из чего сделаны коврики для тренажерного зала?)

Переход:

Однако даже при использовании одних и тех же гранул метод, которым мы запекаем или прессуем коврики, может полностью изменить их молекулярную структуру, что приводит к значительным различиям в твердости.

Как процесс производства меняет текстуру?

Первый параграф:

Разница заключается в вулканизации и полиуретановом скреплении. Вулканизированные коврики сплавляются под сильным нагревом в единый непористый лист, который является твердым и водонепроницаемым. Стандартные коврики с полиуретановым покрытием склеиваются под меньшим давлением, сохраняя естественную эластичность и отскок переработанной резины.

Глубокое погружение:

Это часто самая запутанная часть для покупателей, потому что визуально оба варианта "резиновые". Вулканизированная резина (например, коврики для тяжелой атлетики премиум-класса) проходит химический процесс, аналогичный производству автомобильных шин. Мы подвергаем сырую резину огромному нагреву и давлению, сшивая молекулы. В результате получается невероятно плотный, непористый и практически не сжимающийся материал. Он обеспечивает максимальную устойчивость при подъемах, но нещадно бьет по коленям.

В отличие от, Полиуретановые (PU) связанные маты (стандартная черная плитка для спортзала) бывают "холодного прессования" или "теплого прессования". Гранулы резины остаются отдельными элементами, скрепленными между собой клеем. Поскольку они не расплавляются в единый блок, отдельные гранулы сохраняют способность сжиматься и пружинить. Такой способ производства позволяет получить пол с лучшими амортизационными и звукопоглощающими свойствами, даже если он кажется "мягче" или менее качественным, чем вулканизированный вариант.

Переход:

Иногда мягкость заключается вовсе не в материале. Это инженерная хитрость, спрятанная под ковриком, которую вы не видите сверху.

Может ли конструкция дна создавать "призрачную" мягкость?

Первый параграф:

Да. Плоское дно обеспечивает прочное основание, в котором энергии некуда уходить, поэтому оно кажется более твердым. Вафельное, решетчатое или "пьедестальное" дно создает под ним воздушные полости. Это позволяет коврику прогибаться вниз в пустое пространство, когда на него наступают, создавая "эффект батута".

Глубокое погружение:

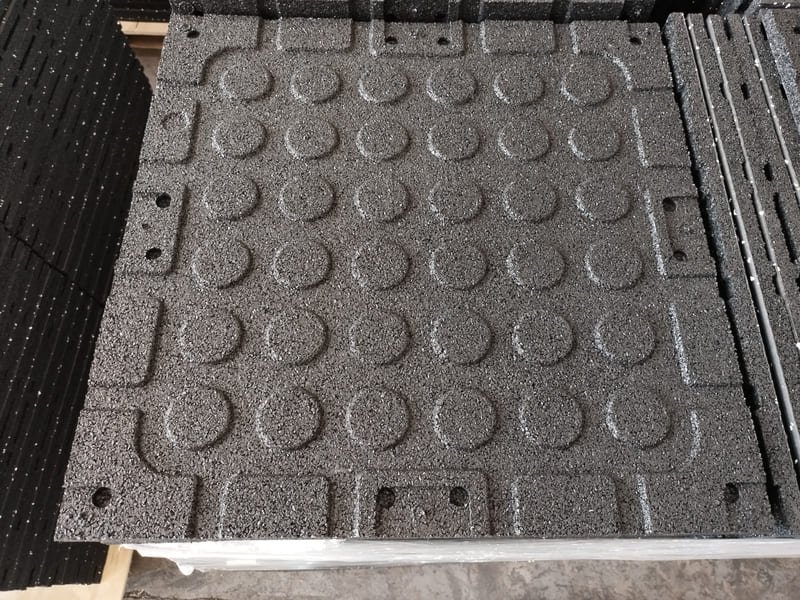

Как руководитель производства, я могу сделать твердую резиновую смесь мягкой, просто изменив форму нижней части формы. Это называется соответствие структуре. A Коврик с плоским дном имеет 100% поверхностный контакт с основанием. Когда вы роняете груз или наступаете на него, сила проходит прямо через резину в бетон. Резина может только сжиматься (сминаться), но не прогибаться (изгибаться).

Тем не менее Коврик с решетчатым или вафельным дном стоит на "ногах". Между ковриком и бетоном есть воздух. Даже если сама резиновая смесь Shore A 80 (очень твердая), при нагрузке вся плитка будет прогибаться в этих воздушных зазорах. Она действует как механическая подвесная система. Такая конструкция отлично защищает основание и обеспечивает дренаж - особенности, которые особенно важны, когда речь идет о Как выбрать подходящие резиновые коврики для улицы?-Но он может казаться "упругим" или менее стабильным при больших статических нагрузках, таких как стойка для приседаний. Это создает фантомную мягкость, обусловленную геометрией, а не химией.

Переход:

Теперь, когда вы разобрались в науке, давайте перейдем к практической части: как вы можете проверить образцы, которые у вас есть в руках?

Как быстро определить разницу в домашних условиях?

Первый параграф:

Вам не нужна лаборатория. Вы можете проверить плотность, взвесив маты (тяжелее = плотнее). Проверьте упругость, вдавив большой палец в поверхность (быстрый отскок = хорошо). Проверьте структуру, перевернув коврик (вафельный или плоский). Наконец, проверьте качество связующего вещества, потерев края (крошки не должны сыпаться).

Глубокое погружение:

Если вы держите в руках два образца и чувствуете себя сбитым с толку, следуйте этому 4-шаговому контрольному списку "Домашняя лаборатория", чтобы сразу определить, с чем вы имеете дело:

- Взвешивание (проверка плотности): Возьмите оба образца в руки. Если они одинаковой толщины, то более тяжелый из них плотнее. Более тяжелые коврики лучше использовать для тяжелых весов, а более легкие - для кардио.

- Пресс для большого пальца (проверка стойкости): Сильно нажмите большим пальцем на центр. Он мгновенно отскакивает назад? Это память резины хорошего качества. Остаются вмятины или ощущение мертвого теста? Это плохое качество переплета.

- Переворот (проверка структуры): Посмотрите на низ. Плоское дно обеспечивает устойчивость для пауэрлифтинга. Сетчатые подошвы обеспечивают амортизацию для плиометрики и дренажа на открытом воздухе.

- Тест на обоняние: Хорошая резина имеет слабый запах. Если мягкий коврик резко пахнет химикатами или тухлыми яйцами, значит, в нем используется низкосортное, токсичное связующее вещество. Не укладывайте его в помещении.

Переход:

Последний шаг - самый важный: решить, какой из этих "ощущений" действительно соответствует вашим конкретным целям тренировок.

Заключение

Не делайте покупки только по толщине. Если вы занимаетесь пауэрлифтингом, выбирайте Высокая плотность/плоское дно для устойчивости. Если вы занимаетесь в студии HIIT, выбирайте Стандартная плотность/сетчатое дно для защиты суставов.

Все еще не уверены, какая плотность подойдет для вашего проекта?

Хватит гадать. Свяжитесь с ЭТАЖ МФ сегодня. Расскажите нам о своем основном стиле тренировок, и мы вышлем вам набор образцов, чтобы вы могли почувствовать разницу между "Стабильным" и "Мягким" перед покупкой.