Rubber gym roll flooring is a durable, elastic floor material primarily made from recycled rubber. It’s manufactured by combining crushed and cleaned recycled SBR (Styrene-Butadiene Rubber) tire rubber with colored EPDM granules. This robust flooring solution provides excellent shock absorption and noise reduction, making it ideal for fitness environments where heavy equipment is used and joint protection is essential.

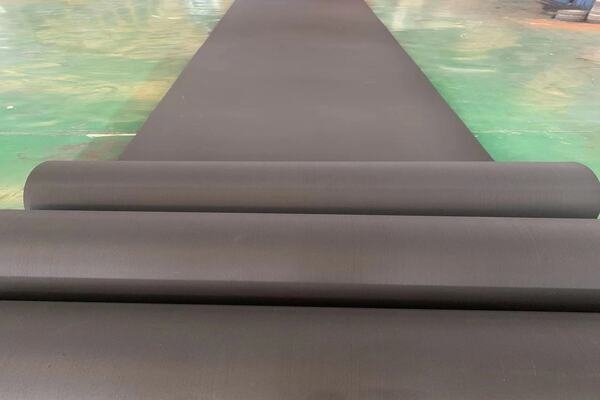

As the production manager at a rubber gym mats factory, I’ve overseen the creation of countless rolls of rubber flooring. Our rubber roll products are typically produced in large rolls, usually 4 feet wide, with thickness options ranging from 1/4 inch to 1/2 inch (6mm to 15mm). This variety allows gym owners and fitness facility managers to select the perfect thickness based on their specific needs and exercise intensity levels.

The main component of our rubber roll flooring is recycled rubber from commercial truck or car tires. This not only gives the material its incredible durability but also makes it an environmentally responsible choice. During production, we carefully process these recycled materials to create a consistent, high-quality product that can withstand the demands of busy fitness facilities.

What makes rubber roll flooring stand out in the fitness industry is its seamless installation and professional appearance. When you walk into a premium gym with that sleek, uniform black floor with colorful speckles, you’re likely looking at rubber roll flooring. Let me walk you through everything you need to know about this versatile gym flooring option.

What is the difference between rubber roll flooring and rubber tiles? Which is more suitable for your venue?

Rubber roll flooring and rubber tiles differ primarily in their installation method and application. Rolls come in large continuous sheets (typically 4ft wide and 25-100ft long) creating fewer seams, while tiles come in smaller squares (usually 2ft×2ft or 1m×1m). Rolls are more suitable for large, open gym spaces requiring a seamless look, while tiles offer easier handling, installation flexibility, and are better for irregularly shaped rooms or DIY projects.

When I consult with clients about their flooring needs, I always consider the specific characteristics of their venue before making a recommendation. The main differences between these two popular options include:

Complessità dell'installazione

Roll flooring requires more planning and typically needs at least two people for installation due to its weight and size. A single roll can weigh several hundred pounds, which makes maneuvering challenging. Tiles, however, can be handled by one person and installed piece by piece, making them more DIY-friendly.

Seam Appearance

One of the biggest advantages of roll flooring is the minimal number of seams. In a large open gym floor, rolls might have a seam every 4 feet, while tiles would have seams every 2 feet in both directions. Fewer seams means less potential for edges to curl up over time and a more professional, continuous appearance.

Adaptability to Space

For irregularly shaped rooms with many corners or obstacles, tiles offer significant advantages. They can be cut and fitted around columns, equipment bases, and odd angles with less waste than rolls. Rolls work best in square or rectangular open spaces with minimal obstructions.

Whether you choose rolls or tiles often comes down to the specific needs of your facility, your installation capabilities, and your budget. For large commercial gyms where professional installation is available, I generally recommend roll flooring for its seamless appearance. For smaller facilities, home gyms, or spaces with unusual layouts, tiles might be the more practical choice.

What are the differences between EPDM granule and pure black rubber roll flooring?

EPDM granule rubber flooring contains colorful Ethylene Propylene Diene Monomer particles mixed with recycled black rubber, creating a speckled appearance with better UV resistance and color stability. Pure black rubber flooring is made entirely from recycled SBR rubber, offering greater cost efficiency but less color variety. EPDM options provide aesthetic versatility and weather resistance, while pure black options deliver maximum value for indoor applications where appearance is secondary to function.

In my years overseeing production, I’ve noticed that the choice between EPDM and pure black rubber flooring often comes down to three key factors: aesthetic preferences, installation location, and budget constraints.

Composition and Appearance

Pure black rubber flooring is made almost entirely from recycled SBR (Styrene-Butadiene Rubber) from vehicle tires, giving it a consistent black color throughout. EPDM-containing flooring has a base of recycled rubber, but we add EPDM granules during production to create color flecks. These can range from subtle 10-20% color flecking to vibrant mixes with up to 50% colored granules.

Durability Factors

Both materials offer excellent durability, but they excel in different environments:

| Caratteristica | EPDM Granule Flooring | Pure Black Rubber Flooring |

|---|---|---|

| Resistenza ai raggi UV | Superior – minimal fading | Moderate – may fade in direct sunlight |

| Color Stability | Maintains color pattern long-term | N/A (uniform black) |

| Hardness | Slightly softer, more comfortable | Slightly firmer, more dense |

| Heat Resistance | Better resistance to heat aging | Good, but may become brittle faster in hot conditions |

| Price | Higher cost due to EPDM content | More economical option |

Application Recommendations

For indoor gyms with large windows and significant natural light, I recommend EPDM options for their UV resistance. For basement gyms, weight rooms, or budget-conscious projects, pure black rubber offers excellent value.

The decision ultimately depends on your priorities. If you’re creating a premium fitness space where aesthetics matter and budget is less restricted, EPDM options create a more visually appealing environment. For practical, high-performance spaces where function takes precedence over form, pure black rubber provides unbeatable value.

Comparison of application scenarios for rubber flooring of different thicknesses (3mm/6mm/8mm/10mm/15mm)

Different rubber flooring thicknesses serve specific purposes: 3mm is ideal for light commercial use with minimal equipment; 6mm works well for moderate-use areas and light free weights; 8mm balances protection and stability for general gym use; 10mm provides enhanced shock absorption for heavy free weight areas; and 15mm offers maximum protection for Olympic lifting zones and extreme impact areas, minimizing noise transfer and floor damage.

Having manufactured rubber flooring in all these thickness options, I’ve gained valuable insights into which thickness works best in different gym environments. The right choice depends primarily on the type of activity, equipment weight, and sound control requirements.

Detailed Thickness Application Guide

3mm (1/8") Flooring

This thinnest option is suitable for:

- Low-impact exercise areas

- Areas with primarily machine-based equipment

- Spaces where equipment stability is paramount

- Commercial spaces with light foot traffic

The 3mm thickness provides basic floor protection but offers minimal shock absorption, making it inappropriate for free weight areas.

6mm (1/4") Flooring

A versatile middle-ground option ideal for:

- Commercial gyms with mixed-use areas

- Home gyms with light free weights (up to 25lbs)

- Areas with cardio machines

- Group exercise rooms for low-impact classes

8mm (5/16") Flooring

This balanced thickness works well for:

- General commercial gym floors

- Functional training areas

- Moderate free weight use

- Home gyms with diverse equipment

10mm (3/8") Flooring

Providing enhanced protection suitable for:

- Heavy free weight areas

- CrossFit boxes

- High-intensity training zones

- Gyms in multi-story buildings requiring noise reduction

15mm (1/2") Flooring

The maximum standard thickness designed for:

- Piattaforme di sollevamento olimpiche

- Specialized strength training zones

- Areas with extremely heavy dumbbells and plates

- Facilities requiring maximum sound damping

When advising gym owners, I always emphasize that erring on the side of thicker flooring is generally safer, especially in multi-purpose spaces. While thinner flooring may reduce initial costs, the long-term protection of your subfloor and equipment, plus the enhanced user experience and noise control provided by thicker options, often justifies the investment for serious training facilities.

Is rubber roll flooring environmentally friendly? Does it have an odour?

Rubber roll flooring is environmentally friendly, typically containing 70-90% recycled rubber from used tires, diverting significant waste from landfills. It does have a distinct rubber odor initially, strongest in the first 2-3 weeks after installation and more noticeable with thicker products. The smell dissipates with time and proper ventilation, and many manufacturers now offer low-VOC options that reduce the initial odor considerably.

As someone who oversees the production of rubber flooring daily, I can speak directly to the environmental aspects and odor characteristics of our products. The environmental benefits extend beyond just recycled content.

Environmental Credentials

Our rubber roll flooring repurposes one of the most problematic waste materials—used tires—which would otherwise take over 80 years to decompose in landfills. A typical 1,000 square foot gym floor installation can repurpose approximately 75-100 car tires, making a significant environmental impact.

Additional environmental benefits include:

- Extremely long lifespan (15-20+ years when properly maintained)

- Minimal chemicals required for cleaning and maintenance

- Potential for future recycling at end of life

- Lower carbon footprint compared to PVC-based synthetic flooring options

Understanding the Odor Factor

The rubber smell comes from compounds called volatile organic compounds (VOCs) naturally present in rubber. I’ve found several factors influence the intensity of this smell:

- Product age: Fresh-from-factory rubber has a stronger smell that diminishes over time

- Installation environment: Temperature and humidity levels affect odor release

- Ventilation: Proper air circulation significantly speeds up odor dissipation

- Manufacturing process: Some manufacturers (including ours) use special processes and treatments to reduce initial odor

For clients concerned about the smell, I recommend:

- Unpacking the rubber rolls in a well-ventilated area 1-2 weeks before installation

- Using fans and open windows during and after installation

- Considering our low-VOC options, which undergo additional processing to reduce odor

- Understanding that the smell is not harmful and will naturally dissipate

In my experience, most gym members barely notice the rubber smell after a month, and it typically becomes completely undetectable within 2-3 months of installation. The environmental benefits and performance advantages make this temporary odor a worthwhile tradeoff for most facility owners.

How do rubber rolls compare to rubber tiles in terms of durability

Rubber rolls and rubber tiles offer comparable overall material durability, both lasting 10-15 years or more in commercial settings. However, rolls have a slight edge in long-term performance due to fewer seams (potential weak points), better weight distribution properties, and more consistent wear patterns. Tiles may show earlier signs of edge wear or separation but offer the advantage of allowing individual piece replacement when damaged, making maintenance more targeted.

Based on my manufacturing experience and feedback from hundreds of installations, I’ve observed how these products perform over time in real-world conditions. Both options are exceptionally durable compared to conventional flooring, but they do show differences in how they age.

Long-Term Performance Factors

The durability differences stem primarily from structural characteristics:

-

Seam Vulnerability

Roll flooring typically has seams every 4 feet in one direction only, while tiles have seams every 2 feet in both directions. These seams, even when perfectly installed, can eventually become weak points where:- Moisture might penetrate to the subfloor

- Edges may begin to curl slightly after years of use

- Heavy equipment movement can cause stress

-

Resistenza agli urti

When heavy weights are dropped, rolls distribute the impact force across a larger continuous surface area. With tiles, the impact may be isolated to a single tile, potentially causing more concentrated damage over time. -

Requisiti di manutenzione

In high-traffic commercial gyms, I’ve observed these typical maintenance patterns:- Rolls: Generally require less frequent adjustments but may need occasional re-adhering at seams after 5-7 years

- Tiles: May need more frequent minor adjustments but allow for selective replacement of damaged sections

The durability equation isn’t one-sided, though. For facilities with extremely heavy use, the ability to replace individual damaged tiles without disrupting the entire floor can be a significant advantage over time. I’ve seen gyms with tile systems strategically replace high-wear areas (like those under squat racks or dumbbell zones) while leaving the rest of the floor intact, effectively extending the overall floor lifespan.

What are the main installation challenges of rubber rolls

The main installation challenges of rubber rolls include their significant weight (150-300 pounds per roll), requiring at least two people to handle; the need for precise measuring and cutting to fit the space perfectly; acclimation requirements of 24-72 hours before installation; subfloor preparation demands; and adhesive application complexity for permanent installations. Large open spaces with minimal obstacles present fewer challenges than irregularly shaped rooms.

Having overseen countless rubber roll installations, I can attest that proper installation is crucial for long-term performance. The challenges vary based on installation method (loose-lay, tape-down, or full-adhesive), but some consistent issues arise across all approaches.

Weight and Handling Difficulties

A typical 4’×25′ roll of 3/8" rubber flooring weighs approximately 200 pounds. This weight makes maneuvering through doorways, around corners, and up stairs particularly challenging. Professional installers typically use:

- Specialized dollies or hand trucks

- Roll movers designed specifically for flooring materials

- Teams of at least 2-3 people per roll

Precise Cutting Requirements

Unlike carpet or vinyl that can be easily trimmed with standard tools, rubber requires:

- Sharp utility knives with frequent blade changes

- Straight edges or T-squares for precise cuts

- Multiple passes for thicker materials (10mm+)

- Careful measurement planning to minimize waste

Subfloor Considerations

Rubber rolls reveal any imperfections in the subfloor beneath them. Before installation, the subfloor must be:

- Perfectly level (maximum 1/8" variance over 10′)

- Clean of all debris, dust, and contaminants

- Moisture-tested and properly sealed if concrete

- Free of cracks, holes, or damage

Adhesive Application Challenges

For permanent installations, applying adhesive correctly requires:

- Proper trowel selection to achieve correct adhesive depth

- Working in sections to ensure adhesive doesn’t dry before the rubber is placed

- Heavy rolling to eliminate air bubbles and ensure proper bonding

- Careful timing around open time and curing time recommendations

From my experience, the most successful installations occur when customers hire professionals with specific experience in rubber flooring. While DIY installation is possible for small spaces, the specialized knowledge and equipment required for large commercial installations typically justify the investment in professional services.

Are rubber rolls more cost-effective for large spaces compared to tiles

Yes, rubber rolls are typically 15-25% more cost-effective than tiles for large spaces (1,000+ square feet). This cost advantage comes from lower per-square-foot material pricing, reduced installation labor (fewer seams to manage), less adhesive required, and decreased waste during installation. The larger and more rectangular the space, the greater the cost savings become compared to tiles.

Working directly with manufacturing costs and customer feedback, I’ve analyzed the economics of both flooring types extensively. The cost equation becomes more favorable for rolls as the installation area increases.

Cost Comparison Breakdown

When considering the total installed cost for a 2,500 square foot commercial gym, here’s a typical breakdown:

| Cost Factor | Rubber Rolls | Rubber Tiles | Risparmi potenziali |

|---|---|---|---|

| Costo del materiale | Lower per sq ft | Higher per sq ft | 10-20% |

| Shipping Cost | Lower (more efficient packing) | Higher (more packaging) | 5-15% |

| Manodopera per l'installazione | Lower (fewer pieces) | Higher (more pieces) | 20-30% |

| Adhesive Required | Less (fewer seams) | More (more seams) | 15-25% |

| Waste Factor | Typically 3-5% | Typically 7-10% | 2-5% |

Beyond the upfront costs, rolls often deliver better long-term value due to:

- Fewer seams that might require future maintenance

- More consistent wear across the surface

- Reduced potential for moisture penetration to the subfloor

Where Tiles May Be More Economical

There are specific scenarios where tiles might actually provide better cost-effectiveness:

- Irregularly shaped rooms with many corners or obstacles

- Phased installations where only a portion of the space is being renovated at a time

- Facilities where access limitations (narrow doorways, stairs) would make roll installation extremely difficult

When advising clients on large installations, I typically recommend requesting quotes for both options. While rolls generally offer better value for large, open spaces, the specific characteristics of each facility might change the equation. For spaces over 5,000 square feet, the cost savings of roll flooring can become substantial enough to significantly impact the overall project budget.

How does the appearance of rubber rolls impact their suitability for different spaces

The appearance of rubber rolls significantly impacts their suitability for different spaces. The sleek, professional aesthetic with minimal seams makes them ideal for premium commercial gyms and fitness studios where brand image matters. Pure black rolls create a more industrial, utilitarian look appropriate for hardcore training facilities, while EPDM color-flecked options offer versatility for fitness spaces aiming to match brand colors or create a more energetic environment.

In my role, I’ve noticed that the visual impact of flooring choices is often underestimated during the planning phase but becomes a defining characteristic of the space once installed. Here’s how appearance factors into suitability:

Aesthetic Considerations By Facility Type

Different facility types have distinct appearance needs:

-

Premium Commercial Gyms

The continuous, seamless look of rolls creates an upscale, professional appearance. These spaces often prefer:- Moderate EPDM flecking (10-20%)

- Consistent color distribution

- Perfectly aligned seams for minimal visual interruption

-

Boutique Fitness Studios

These specialized spaces often use flooring to reinforce their brand identity:- Custom EPDM color combinations matching logo colors

- Higher percentage of colorful flecking (30-50%)

- Precise installation creating clean lines and borders

-

Powerlifting/Strength Training Facilities

Function-focused spaces typically prefer:- Pure black or minimal fleck appearance

- Durability-focused aesthetic that embraces the industrial look

- Thickness visual cues that communicate safety and quality

-

Multi-Purpose Facilities

Spaces combining different training styles benefit from:- Zone differentiation using varying colors or fleck densities

- Visual transitions between functional areas

- Wayfinding elements incorporated into the flooring design

Psychology of Flooring Appearance

The color and appearance of flooring can influence user perception and behavior:

- Darker flecking tends to hide dust and minor soiling between cleanings

- Lighter flecks create a more energetic, open feeling

- Visual consistency communicates attention to detail and professionalism

When helping clients select the right appearance, I recommend they consider their target member demographic, the types of activities performed in the space, the overall design scheme, and practical maintenance concerns. The right aesthetic choice enhances both the perceived value of the facility and the exercise experience itself.

What are the benefits of using rubber rolls in high-impact zones like gyms

The key benefits of rubber rolls in high-impact gym zones include superior shock absorption protecting both joints and subfloors, exceptional noise reduction from dropped weights and equipment, impressive durability under heavy use, minimal maintenance requirements, and the professional seamless appearance that elevates facility perception. These benefits directly translate to enhanced user experience, equipment longevity, and reduced building structural stress.

After years of working with gym owners and witnessing how our flooring performs in the most demanding environments, I’ve identified specific benefits that make rubber rolls particularly valuable in high-impact training areas.

Performance Benefits

-

Impact Protection System

The layered structure of quality rubber rolls creates a sophisticated impact management system:- Initial impact force absorption by the surface layer

- Energy dispersion throughout the rubber matrix

- Gradual transfer of reduced force to the subfloor

This system protects not just the building structure but also the users’ joints during plyometric exercises, heavy landings, and dropped weights.

-

Acoustic Performance

In multi-level buildings or gyms with neighbors, the noise reduction properties become critical:- Typical impact noise reduction of 15-25 decibels compared to concrete

- Vibration damping preventing sound transfer through building structures

- Higher thickness options (10mm+) providing enhanced acoustic benefits

-

Surface Stability

Unlike foam-based alternatives that can compress permanently, quality rubber maintains its performance characteristics:- Minimal compression set (permanent deformation) even under heavy equipment

- Consistent rebound properties maintaining exercise effectiveness

- Stable surface for dynamic movements and proper foot positioning

-

Return on Investment Factors

The economic benefits extend beyond initial cost:- Extended subfloor lifespan by preventing impact damage

- Reduced equipment damage from drops and falls

- Lower maintenance costs compared to other flooring options

- Potential insurance premium benefits due to injury risk reduction

In high-impact training zones, I’ve consistently observed that facilities installing proper rubber roll flooring experience fewer member complaints, reduced equipment maintenance issues, and significantly less building damage. The initial investment in quality rubber flooring typically pays dividends through extended facility lifespan and enhanced member experience.

Conclusione

Rubber gym roll flooring provides an optimal balance of durability, shock absorption, and professional appearance for fitness facilities. Made from recycled materials, it offers environmental benefits while delivering superior performance in high-impact zones, with variations in thickness and color to suit different applications and design preferences.