Gym mats are primarily constructed from rubber, foam, and PVC materials, with rubber being the dominant choice in American fitness facilities. As a production manager at a leading gym flooring manufacturer, I’ve seen rubber mats account for over 70% of commercial gym flooring in the US due to their exceptional durability, shock absorption, and ability to withstand heavy equipment.

The American fitness industry has specific requirements that have shaped our manufacturing priorities over the years. Having overseen production for facilities across all 50 states, I’ve gained valuable insights into what materials work best for different applications. While various materials have their place, rubber has emerged as the gold standard for most commercial and home gym settings in the United States.

Let me take you through the complete breakdown of gym mat materials with a special focus on rubber products, which have revolutionized the fitness flooring industry in America.

Are There Any Eco-Friendly Materials Used In Gym Mats?

Yes, eco-friendly gym mats are increasingly popular in the US market, with recycled rubber leading the charge. Our American facilities now produce mats using up to 90% recycled rubber from used tires, diverting over 25 million pounds of rubber from landfills annually. This aligns with growing sustainability demands from US gym chains and LEED-certified buildings.

The American Rubber Recycling Revolution

The rubber recycling process in our US facilities follows several key steps:

- Collection and sorting of used tires from American automotive centers

- Mechanical shredding and steel wire removal

- Granulation to specific sizes (typically 1-10mm depending on application)

- Cleaning and contaminant removal

- Mixing with EPDM color flecks (for aesthetic options) and binding agents

- Compression molding under heat and pressure

- Cooling and quality control testing

- Cutting to standard American dimensions (typically 4’×6′ or 4’×8′ mats)

This process has been refined specifically for the American market, where recycled rubber mats now represent nearly 60% of all commercial gym flooring installations. The sustainability factor has become especially important as more US facilities seek LEED certification points through their flooring choices.

Environmental consciousness has become a significant factor in American gym design, with many franchises making sustainability part of their brand identity.

How Do I Choose The Right Thickness For Rubber Gym Mats?

The right rubber mat thickness depends on your specific usage scenario. For American commercial gyms, 3/8" (8-10mm) is standard for general areas, 1/2" (12-15mm) for free weight zones, and 3/4"-1" (19-25mm) for heavy Olympic lifting platforms. Home gyms typically use 8mm mats for light equipment and 3/8" for free weights.

Thickness Guidelines For Different Applications in American Gyms

Based on our experience supplying thousands of American facilities, here are the recommended thicknesses:

| Thickness | US Measurement | Best For | Typical Price Range (US) |

|---|---|---|---|

| 6-8mm | 1/4" | Yoga/cardio areas, light equipment | $1.50-2.50/sq ft |

| 8-10mm | 3/8" | General gym floors, moderate weights | $2.00-3.50/sq ft |

| 12-15mm | 1/2" | Free weight areas, heavy equipment | $2.75-4.50/sq ft |

| 19-25mm | 3/4"-1" | Olympic lifting platforms, extreme weights | $3.50-6.00/sq ft |

| 30-50mm | 1.25"-2" | Specialized drop zones, CrossFit boxes | $5.00-9.00/sq ft |

American gym operators have specific expectations for flooring performance based on these thickness ranges. Most commercial facilities in the US opt for graduated thickness zones, with thicker mats in free weight areas and thinner options in cardio zones. This approach optimizes both performance and budget.

The increased thickness provides crucial benefits for American fitness trends:

- Impact absorption: Critical for popular high-intensity workouts like CrossFit

- Noise reduction: Essential in multi-story buildings and apartment complexes

- Subfloor protection: Necessary to protect expensive concrete and wood subfloors

- Equipment stability: Thicker mats provide better stability for heavy equipment

Understanding thickness requirements has become especially important with the rise of home gyms during the pandemic, which created unprecedented demand for residential gym flooring solutions.

What Are Different Materials Used For In American Gym Settings?

In American facilities, rubber dominates free weight areas and high-traffic zones (70% of commercial installations), EVA foam is preferred for group fitness and yoga studios (15%), PVC/vinyl is common in cardio and machine areas (10%), and specialized materials like turf and cork serve niche applications (5%) like functional training zones.

Material Applications In American Fitness Facilities

The US fitness market has developed clear preferences for specific materials in different zones:

| Material | Primary Applications | Average Lifespan | Cost Range (US) |

|---|---|---|---|

| Rubber (Recycled) | Free weight areas, general gym floors | 7-10 years | $2-4/sq ft |

| Rubber (Virgin/EPDM) | Premium areas, outdoor facilities | 10-15 years | $4-7/sq ft |

| EVA Foam | Group fitness studios, home gyms, yoga areas | 2-5 years | $1-3/sq ft |

| PVC/Vinyl | Cardio areas, machine zones, locker rooms | 5-8 anni | $3-6/sq ft |

| Erba artificiale | Functional training zones, sled tracks | 3-7 years | $5-8/sq ft |

| Cork | Yoga studios, boutique fitness, barre studios | 3-5 years | $4-7/sq ft |

| Wood | Basketball courts, group fitness rooms | 20-30+ years (with refinishing) | $7-12/sq ft |

EVA Foam Applications

EVA foam has found its niche in American fitness through specific applications:

- Group fitness studios: The cushioning is ideal for high-impact classes like HIIT and aerobics

- Yoga and Pilates spaces: The softer surface provides comfort for floor exercises

- Home gyms: Lightweight, easy installation, and lower cost make it popular for residential use

- Children’s areas: The softer, safer surface is perfect for kids’ zones in family fitness centers

- Martial arts dojos: The shock absorption protects against falls and throws

The primary limitation of EVA in American facilities is its significantly shorter lifespan and susceptibility to damage from heavy equipment, which restricts its use primarily to bodyweight exercise zones.

The strategic zoning of different materials has become standard practice in US gym design to optimize both functionality and budget.

How Long Do Different Gym Mat Materials Last And How Do I Maintain Them?

In American commercial environments, rubber mats typically last 7-10 years, PVC/vinyl 5-8 years, and EVA foam 2-5 years. Proper maintenance extends lifespan by 30-50%. For rubber, I recommend daily sweeping, weekly cleaning with neutral pH cleaners, and quarterly deep cleaning with specialized rubber rejuvenators common in US facilities.

Lifespan And Maintenance Guide For American Gym Operators

Maintenance requirements vary significantly by material and usage intensity:

| Material | Commercial Lifespan | Home Gym Lifespan | Requisiti di manutenzione |

|---|---|---|---|

| Rubber | 7-10 years | 10-15+ years | Daily sweeping, weekly neutral pH cleaning, quarterly deep cleaning |

| EVA Foam | 2-5 years | 5-8 anni | Daily sweeping, weekly mild soap cleaning, avoiding harsh chemicals |

| PVC/Vinyl | 5-8 anni | 8-12 years | Daily sweeping, weekly disinfecting, waxing every 6-12 months |

| Cork | 3-5 years | 5-7 years | Regular sweeping, monthly cleaning with cork-specific cleaners |

| Erba artificiale | 3-7 years | 7-10 years | Weekly vacuuming, monthly deep cleaning, quarterly grooming |

Rubber Mat Maintenance Protocol for US Facilities

Our recommended maintenance schedule for rubber flooring in American gyms:

- Giornaliero: Dust mop or vacuum to remove abrasive particles

- Settimanale: Clean with a neutral pH cleaner (pH 7-9) using an auto-scrubber or mop

- Mensile: Inspect for damage, address any stains with targeted spot treatment

- Trimestrale: Deep clean with rubber-specific cleaner to restore surface and remove embedded oils

- Annualmente: Professional deep cleaning and assessment of overall condition

American gym operators should avoid these common mistakes:

- Using high-pH cleaners (above 10) which break down the rubber

- Applying petroleum-based products that degrade the material

- Using excessive water during cleaning (especially on tile systems with seams)

- Neglecting chalk dust, which becomes abrasive when compressed

Proper maintenance has become particularly important as American consumers increasingly evaluate facility cleanliness as a primary factor in gym selection.

Where Can I Purchase Gym Mats At The Best Prices In The US?

In the US market, the best value for commercial rubber gym flooring comes from direct manufacturers and specialized fitness flooring distributors ($2-4/sq ft). For home use, online retailers like Rogue Fitness, Rep Fitness, and Amazon offer good quality at competitive prices ($1.50-3/sq ft). Big box stores provide budget options but typically with shorter warranties.

American Purchasing Options And Price Comparisons

The US market offers several purchasing channels with distinct advantages:

| Source | Pros | Cons | Price Range (Rubber) | Best For |

|---|---|---|---|---|

| Direct Manufacturers | Highest quality, custom options, longest warranties | Higher minimums, longer lead times | $2-4/sq ft | Commercial facilities |

| Specialty Distributors | Expert advice, installation services, good selection | Higher prices than direct | $2.50-5/sq ft | New gym build-outs |

| Fitness Equipment Retailers | Verified gym-specific products, good warranties | Limited selection, moderate prices | $2-4/sq ft | Home gyms, small studios |

| Online Marketplaces | Convenience, competitive pricing, reviews | Variable quality, limited support | $1.50-3.50/sq ft | Budget home gyms |

| Big Box Stores | Immediate availability, low entry price | Limited thickness options, shorter lifespan | $1-2.50/sq ft | Temporary solutions |

Recommended US Retailers By Category

Based on our industry experience, these are the top American sources for gym flooring:

Commercial Grade:

- Ecore Athletic

- Regupol America

- Rubber Flooring Inc.

- American Floor Mats

- Flooring Inc.

Home Gym Specialists:

- Rogue Fitness

- Rep Fitness

- Titan Fitness

- American Barbell

- FringeSport

For budget-conscious home gym owners, timing purchases around major US sales events can yield significant savings:

- Black Friday/Cyber Monday (November)

- New Year fitness sales (January)

- Memorial Day weekend (May)

- Labor Day weekend (September)

When purchasing, American consumers should always verify warranty terms and shipping costs, which can significantly impact the total price, especially for heavy rubber products.

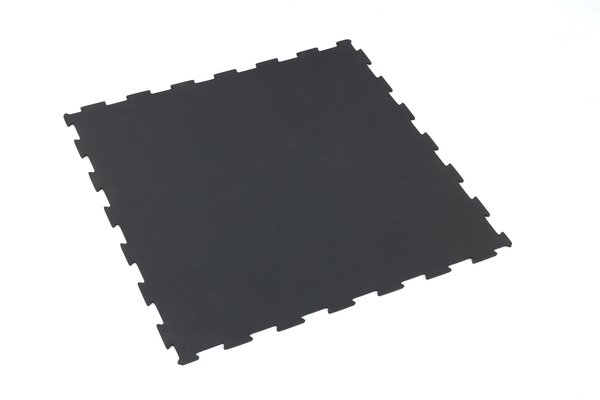

How Is Rubber Gym Flooring Manufactured?

Rubber gym flooring manufacturing in American facilities involves precise processes beginning with raw material preparation (virgin or recycled rubber), mixing with binding agents and colorants, compression molding under heat (330-350°F) and pressure (1500-2000 psi), followed by cooling, quality testing, and precision cutting to US standard dimensions.

The American Rubber Flooring Production Process

As a production manager, I can share the detailed steps in our US manufacturing facilities:

-

Raw Material Preparation:

- Recycled rubber: Tires are shredded, steel removed, and rubber ground to precise granule sizes

- Virgin rubber: EPDM or SBR rubber is processed into workable form

- Supporting materials: Binders (polyurethane), colorants, and additives are prepared

-

Mixing Phase:

- Precise ratios of rubber granules (typically 80-90%)

- Polyurethane binders (7-15%)

- Colorants and additives (3-5%)

- Mixed in industrial tumblers for consistent distribution

-

Forming Process:

- For tiles and mats: The mixture is poured into molds

- For rolled rubber: The mixture is fed into a calendar press system

- Material is compressed under high pressure (1500-2000 psi)

- Heat is applied (330-350°F) to activate binding agents

-

Curing Phase:

- Material is held under heat and pressure for 20-40 minutes

- This creates permanent cross-linking of the rubber polymers and binders

- Cooling period follows to stabilize the material structure

-

Finishing Operations:

- Precision cutting to standard American dimensions

- Surface texturing (if specified)

- Edge treatments (straight cut, interlocking, puzzle)

- Quality control inspection

-

Testing Procedures:

- Density testing to ensure consistent weight and performance

- Durometer testing for hardness/softness

- Tensile strength evaluation

- Impact resistance verification

- Dimensional stability checks

This manufacturing process has been optimized specifically for the American market, where consistent quality and adherence to strict safety standards are paramount.

Conclusione

Rubber dominates the American gym flooring market due to its durability and versatility. Thickness selection should match specific usage scenarios, from 1/4" for cardio areas to 1" for Olympic lifting. Different materials serve distinct purposes, with lifespans ranging from 2-15 years depending on material and maintenance practices.