Outfitting a full barn with stall mats typically costs between $3.00 to $5.00 per square foot. For standard 12’x12′ stalls, budget $450-$500 per stall. A 10-stall barn would run approximately $4,500-$5,000 for quality rubber mats. These costs vary based on mat thickness, material quality, and installation requirements.

As a production manager at a rubber flooring factory for over 15 years, I’ve guided countless barn owners through the process of selecting and budgeting for stall mats. The investment in quality rubber flooring is significant but offers tremendous value through reduced bedding costs, improved cleaning efficiency, and better horse health outcomes. I regularly speak with customers who report their mats paying for themselves within 1-2 years through bedding savings alone.

When calculating your barn flooring budget, several factors come into play beyond just the raw square footage. Mat thickness ranges from 1/2" economy options to premium 3/4" or 1" versions that offer greater durability and insulation. Material composition varies from basic recycled rubber to premium blends with antimicrobial properties. Installation complexity – whether you’re using interlocking systems or standard mats – also impacts your bottom line.

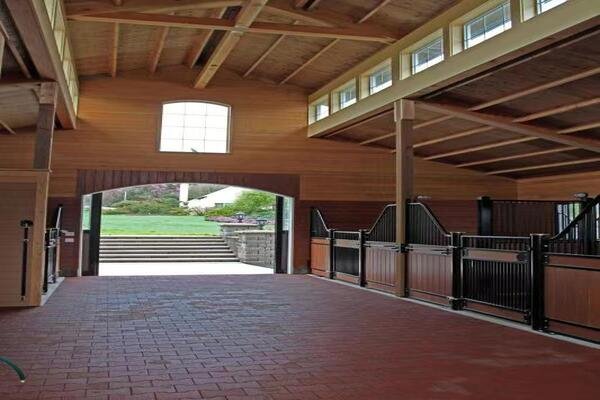

Before diving deeper into specific costs, I recommend measuring your stalls precisely and considering your specific needs. A competition facility with high-end horses may require different flooring solutions than a hobby farm. Through my work consulting with various equestrian facilities, I’ve found that understanding the complete cost picture upfront prevents expensive surprises later.

What factors determine the total cost of stall mat installation?

The total cost of stall mat installation depends on your barn’s square footage, mat thickness (typically 1/2" to 1"), material quality (recycled vs. virgin rubber), installation complexity, and delivery distance. Labor costs add $2-$3 per square foot if professionally installed. For a 10-stall barn, these factors can create a price range from $4,000 for basic DIY installation to $8,000+ for premium professionally-installed solutions.

Key Cost Factors to Consider

When I consult with barn owners, I break down pricing into these essential components:

| عامل التكلفة | Price Impact | Notes |

|---|---|---|

| Square Footage | $3-$5 per sq ft | Basic calculation starting point |

| Mat Thickness | +$0.50-$1 per sq ft per 1/4" | Thicker mats cost more but last longer |

| جودة المواد | +$0-$2 per sq ft | Premium blends cost more |

| نوع التثبيت | +$0-$3 per sq ft | DIY vs. professional installation |

| Delivery Distance | $100-$500+ | Depends on your location relative to suppliers |

| Subfloor Preparation | $0-$1,000+ | Existing floor condition matters significantly |

I’ve witnessed many customers focus solely on the base mat price without considering these other factors. Last month, I worked with a barn owner in Kentucky who initially budgeted $4,000 for a 10-stall renovation, only to discover her uneven concrete subfloors required significant preparation work. The final project cost was closer to $6,000. Had she accounted for this from the beginning, she could have planned her renovation timeline more effectively.

Understanding these variables gives you a more realistic budget picture. When customers call me for quotes, I always ask about their subfloor condition and whether they plan to install the mats themselves. These two factors alone can swing your final cost by thousands of dollars.

How do different stall mat types and materials affect pricing?

Stall mat prices vary significantly by material and design. Basic recycled rubber mats cost $2.50-$3.50 per square foot. Premium virgin rubber adds $1-$2 per square foot but offers better durability and less odor. Interlocking systems cost 15-25% more than straight-edge mats but reduce installation time. Specialty mats with antimicrobial properties or custom cushioning can reach $7-$8 per square foot.

Material Comparison Chart

In my factory, we produce several distinct rubber flooring options, each with different price points:

| Mat Type | Price Range (per sq ft) | المتانة | الأفضل لـ |

|---|---|---|---|

| Basic Recycled | $2.50-$3.50 | 5-7 سنوات | Budget-conscious barns |

| Premium Recycled | $3.50-$4.50 | 7-10 سنوات | Most standard applications |

| Virgin Rubber | $4.50-$6.00 | 10-15+ years | High-traffic, competition barns |

| Specialty/Antimicrobial | $6.00-$8.00 | 10-15+ years | Veterinary, foaling stalls |

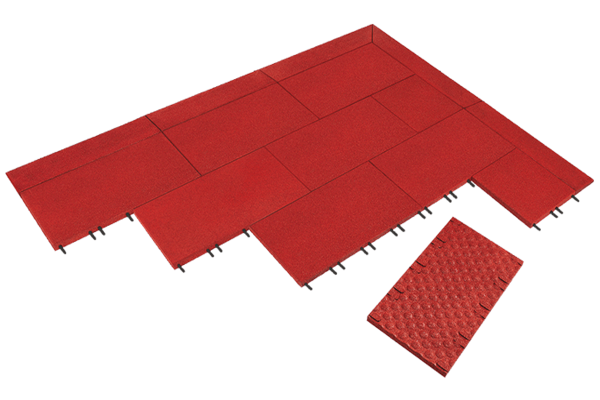

| Interlocking System | +15-25% over base price | Varies by base material | Easier installation, fewer seams |

I recently consulted with a dressage facility that initially wanted our most economical recycled rubber option. After discussing their high-end operation and the impressive horses they house, they upgraded to our premium virgin rubber with antimicrobial properties. While this increased their budget by about 40%, the owner understood that the premium material would maintain its appearance longer, release fewer odors, and provide better cushioning for their valuable competition horses.

Material selection goes beyond just the upfront cost. Our recycled rubber products utilize post-consumer tire rubber, making them more economical and environmentally friendly, but they do have a distinct rubber smell initially. Virgin rubber costs more but has minimal odor and more consistent performance characteristics.

When evaluating materials, consider the expected lifespan of your installation. Investing in higher-quality materials often results in lower annual costs when calculated over the full lifespan of the product.

What is the typical price range for standard stall mats?

Standard 4’x6′ stall mats (3/4" thick) typically cost between $45-$75 each. For 10’x10′ stalls, expect to use 4-5 mats costing $180-$375 total per stall. Larger 12’x12′ stalls require 6 mats, bringing the cost to $270-$450 per stall. Premium stall mat kits designed for specific stall sizes run $400-$500 for complete coverage with minimal cutting.

Standard Mat Pricing Details

The most common stall mat size we produce is the 4’x6′ mat at 3/4" thickness. This size balances manageable weight (approximately 100 pounds per mat) with efficient coverage. Based on my production data:

| Mat Size | السُمك | نطاق السعر | Weight | Coverage |

|---|---|---|---|---|

| 4’x6′ | 3/4" | $45-$75 | ~100 lbs | 24 sq ft |

| 4’x8′ | 3/4" | $60-$100 | ~135 lbs | 32 sq ft |

| 3’x4′ | 3/4" | $30-$50 | ~50 lbs | 12 sq ft |

| Custom Kit (10’x10′) | 3/4" | $400-$450 | ~400 lbs | 100 sq ft |

| Custom Kit (12’x12′) | 3/4" | $450-$500 | ~600 lbs | 144 sq ft |

I’ve found that most customers prefer purchasing individual mats despite the additional work required to cut and fit them. This approach typically saves 10-15% compared to pre-designed kits, though it does require more labor during installation. For a recent customer with a 6-stall barn, this choice saved them approximately $300 on their overall project.

From my experience overseeing thousands of mat orders, about 30% of customers opt for the convenience of stall kits despite the premium price. These kits provide pre-sized mats that minimize or eliminate cutting, significantly reducing installation time and frustration.

The weight of these mats is a crucial consideration that many customers overlook. Standard 4’x6′ mats weighing 100 pounds each require at least two people for safe handling. I always recommend having additional help available on installation day to prevent injury and damage to the mats.

How can you estimate the total budget for your barn size?

To estimate your barn’s stall mat budget, multiply your total square footage by $3-$5 per square foot. For a 6-stall barn with 12’x12′ stalls (864 sq ft), budget between $2,600-$4,300 for materials. Add 15% for cutting waste and $2-$3 per square foot for professional installation if needed. Include $200-$500 for delivery and $100-$300 for tools and supplies if installing yourself.

Budget Calculation Formula

As someone who helps barn owners plan their flooring projects daily, I’ve developed a simple formula for estimating total costs:

Total Budget = (Square Footage × Base Mat Cost) + Waste Factor + Installation + Delivery + Tools

For a practical example, let’s calculate the budget for a medium-sized barn:

| Calculation Component | Formula | 6-Stall Example (12’×12′) |

|---|---|---|

| Total Square Footage | Stall Size × Number of Stalls | 144 sq ft × 6 = 864 sq ft |

| Base Mat Cost | Square Footage × $3-$5 | 864 sq ft × $3-$5 = $2,592-$4,320 |

| Waste Factor (15%) | Base Mat Cost × 0.15 | $389-$648 |

| Professional Installation (optional) | Square Footage × $2-$3 | $1,728-$2,592 |

| Delivery | Flat fee based on distance | $200-$500 |

| DIY Tools & Supplies | Flat fee if self-installing | $100-$300 |

| TOTAL (DIY) | $3,281-$5,768 | |

| TOTAL (Professional) | $4,909-$8,060 |

Last year, I helped a customer plan a similar 6-stall barn project. By purchasing during our factory’s off-season promotion (typically January-February), they saved nearly 20% on materials. Timing your purchase can significantly impact your budget.

I always emphasize the importance of accurate measurements. Adding an extra 15% for waste accounts for cutting, fitting around posts, and occasional damaged mats. This buffer prevents the frustration of running short during installation and having to wait for additional materials to arrive.

Beyond the obvious mat costs, be prepared for hidden expenses like subfloor preparation ($1-$3 per square foot), specialty cutting tools ($50-$200), adhesives for sloped floors ($100-$300), seam sealants ($75-$150), and potential freight upcharges for remote locations ($100-$500). Professional installation adds $2-$3 per square foot, while replacement costs from improper installation can double your expense.

Common Hidden Costs Table

In my years helping customers through installations, I’ve identified these frequently overlooked expenses:

| Hidden Cost | Typical Range | When It Applies |

|---|---|---|

| Subfloor Leveling | $1-$3 per sq ft | Uneven concrete, dirt floors |

| Moisture Barriers | $0.50-$1 per sq ft | Damp conditions, dirt floors |

| Specialty Cutting Tools | $50-$200 | DIY installation |

| Adhesives | $100-$300 | Sloped floors, wash areas |

| Seam Sealants | $75-$150 | Veterinary requirements, wash areas |

| Removal of Old Flooring | $1-$2 per sq ft | Replacement projects |

| Freight Surcharges | $100-$500 | Remote locations |

| Lift Gate Service | $50-$150 | No forklift available |

| Weekend Delivery | $50-$200 | Scheduling constraints |

I experienced this firsthand when helping a client in Montana who didn’t account for their remote location. The freight surcharge added nearly $400 to their project. Had they known this upfront, they might have coordinated with neighboring farms to share delivery costs.

Subfloor preparation is perhaps the most commonly underestimated expense. Just last month, a customer discovered their concrete had significant cracks and uneven areas that required filling and leveling before installation. This added three days and approximately $900 to their project timeline and budget.

My advice: always inspect your subfloor thoroughly before ordering mats, and budget an additional 20-30% beyond the base mat cost for these potential hidden expenses. This buffer has saved many customers from difficult financial conversations midway through their projects.

How do you choose cost-effective stall mats without sacrificing quality?

To maximize value, focus on mat density (aim for 60-65 lbs per cubic foot) rather than just thickness. Choose mats with 5+ year warranties, opt for standard sizes to avoid cutting waste, buy direct from manufacturers when possible, and consider bulk purchasing with fellow barn owners. Avoid the cheapest options which typically degrade quickly, and target the middle price tier for the best balance of quality and affordability.

Value-Maximizing Strategies

Through my factory experience, I’ve identified several strategies that help customers get the most value:

| الاستراتيجية | Potential Savings | Quality Impact |

|---|---|---|

| Focus on Density | 10-15% | Maintains or improves quality |

| Standard Sizes | 5-10% | No impact |

| Direct Purchasing | 10-30% | No impact |

| Bulk Ordering | 10-20% | No impact |

| Seasonal Promotions | 10-25% | No impact |

| التركيب الذاتي | 30-40% of total project | Depends on skill |

| Mid-Tier Products | 15-25% vs premium | Minimal for most applications |

One customer I worked with last year formed a buying group with three neighboring farms. By placing a combined order that filled an entire shipping container, they each saved nearly 20% compared to individual purchases. This approach requires coordination but delivers significant savings.

Regarding quality indicators, I always advise customers to examine:

- Mat density (heavier mats typically last longer)

- Edge quality (clean, straight cuts indicate better manufacturing)

- Surface texture (consistent texture suggests proper vulcanization)

- Warranty length (longer warranties indicate manufacturer confidence)

The most cost-effective approach I’ve observed is purchasing mid-tier products directly from manufacturers like us during promotional periods. This strategy typically yields 20-30% savings compared to retail pricing while maintaining appropriate quality for most applications.

What are common buyer mistakes and how can you avoid them?

Common stall mat purchasing mistakes include underestimating required quantities, choosing mats too thin for your application, ignoring subfloor preparation requirements, selecting the wrong material for your climate, and failing to account for freight costs. Avoid these errors by measuring accurately, consulting with experts about appropriate thickness, properly preparing subfloors, selecting climate-appropriate materials, and getting detailed shipping quotes.

Common Mistakes and Solutions

In my 15 years overseeing rubber flooring production, I’ve witnessed these recurring mistakes:

| الخطأ الشائع | Consequence | Prevention Strategy |

|---|---|---|

| Inaccurate Measurements | Running short or wasting money | Measure each stall individually; don’t assume uniform size |

| Inadequate Thickness | Premature failure, especially in heavy horse stalls | Match thickness to horse size and activity level |

| Neglected Subfloor Preparation | Uneven wear, mat movement, reduced lifespan | Properly level and clean subfloor before installation |

| Improper Material for Climate | Excessive expansion/contraction, odor issues | Select appropriate rubber compound for your region |

| Underestimated Freight Costs | Budget surprises, delivery delays | Get detailed quotes including all potential surcharges |

| DIY Installation Without Proper Tools | Poorly fitted mats, gaps, lifting edges | Invest in proper cutting tools and techniques |

| Choosing Price Over Quality | Frequent replacements, higher long-term costs | Focus on value (lifespan ÷ cost) rather than lowest price |

I recently spoke with a customer who ordered based on her architect’s barn plans rather than measuring her actual built stalls. The stalls ended up being 6 inches larger in each dimension than the plans indicated, resulting in significant additional cutting and a shortage of materials that delayed project completion by two weeks.

Another customer in Florida selected our dense recycled rubber product designed for northern climates. This denser material retained heat excessively in their hot environment, creating uncomfortable stall temperatures and stronger odors than our climate-specific formulation would have produced.

My best advice comes from observing thousands of successful installations: take the time to consult with manufacturers about your specific application and environment. The 30 minutes spent discussing your project with an expert can prevent days of frustration and thousands in unnecessary expenses.

Why is it important to get a detailed quote from your supplier?

A detailed supplier quote prevents budget surprises by specifying exact mat quantities, material specifications, accurate delivery costs including potential surcharges, warranty terms, and installation requirements. Comprehensive quotes also outline payment terms and return policies. Without this documentation, customers often face unexpected charges averaging 15-30% above initial estimates, delivery delays, and warranty disputes.

Essential Quote Components

As a factory manager who reviews quotes daily, I insist that our sales team include these critical elements:

| Quote Component | Why It Matters | Red Flags to Watch For |

|---|---|---|

| Itemized Material List | Confirms exact quantities and specifications | Vague descriptions, missing dimensions or thickness |

| Detailed Freight Costs | Accounts for weight, distance, and special services | "Shipping TBD" or unclear delivery terms |

| شروط الضمان | Documents your protection against defects | Limited or unclear coverage periods |

| Installation Requirements | Clarifies DIY vs. professional needs | Missing subfloor specifications |

| Payment Schedule | Establishes clear financial expectations | Excessive deposits or unclear final payment terms |

| Return/Exchange Policy | Protects against incorrect or damaged materials | Restocking fees over 20% or no return option |

| Lead Time | Sets realistic project timeline | Vague delivery windows or excessive lead times |

I recall a customer who received a quote that simply listed "rubber stall mats" without specifying thickness or density. When the mats arrived, they were significantly lighter than expected – a 1/2" economy product rather than the 3/4" premium product discussed. Because the quote lacked specificity, resolving the situation became unnecessarily complicated.

Another situation involved unclear freight terms that didn’t specify the need for a forklift at delivery. The customer had to pay an unexpected $125 lift gate fee plus $200 for redelivery after the initial attempt failed – expenses that proper quote documentation would have anticipated.

When requesting quotes, I advise customers to specifically ask for "all-inclusive pricing" that accounts for every potential charge. This simple phrase prompts suppliers to conduct a more thorough evaluation of your project requirements and potential challenges, resulting in more accurate budgeting.

الخاتمة

Outfitting a barn with quality stall mats typically costs $3-$5 per square foot, with total investments ranging from $450-$500 per standard stall. For best results, focus on mat density, prepare subfloors properly, and get comprehensive quotes to avoid costly surprises.